You want your log splitter to work for many years. Doing regular log splitter maintenance helps you find problems early. It also keeps your machine working well. Look at this table to see how a step-by-step guide can help:

Impact on Lifespan |

|

|---|---|

Regular maintenance |

Makes it last longer |

Preventive checks |

Stops breakdowns |

Timely repairs |

Makes it work better |

If you follow a step-by-step guide, you can save money. You also get better and more steady performance.

Key Takeaways

Taking care of your log splitter is very important. It makes your log splitter work well and last longer.

You should always look at the hydraulic fluid before you use it. If the fluid is too low, it can break your log splitter and make it work badly.

Look at your log splitter before and after you use it. This helps you find problems early and keeps you safe.

Why Log Splitter Maintenance Matters

Benefits of Regular Maintenance

You want your log splitter to work well each time. Doing regular maintenance helps you get good results. It also keeps you safe when you use the machine. Taking care of your log splitter stops problems before they start. This means you do not get slowed down or put in danger. Look at this table to see what you get from taking care of your log splitter:

Benefit |

Description |

|---|---|

Optimal Performance |

Regular maintenance helps your log splitter work its best. |

Safety |

Checking your machine often helps prevent accidents and problems. |

Longevity |

Good care makes your log splitter last longer and saves money. |

You save money because your log splitter works for more years. You do not need to fix it as much or buy a new one soon. When you keep up with maintenance, you split wood faster and safer.

Risks of Neglecting Care

If you do not take care of your log splitter, you can have problems. Low hydraulic fluid can make your machine shake and get loud. This can break your log splitter and make it hard to use. Here are some risks you should know:

Low hydraulic fluid can hurt the system and make it work worse.

Lots of shaking and noise can make it hard to use.

Not checking for safety can cause accidents.

Not cleaning or adding oil can make it break down.

Not looking for damage can put you and your log splitter in danger.

Did you know most wood-splitter injuries happen when people are relaxing? Almost half of these injuries hurt fingers badly. Many accidents happen when people try to fix stuck wood while the machine is on. This shows why safety and regular care are important. If you pay attention to safety and maintenance, you protect yourself and your log splitter.

Log Splitter Inspection Tips

Keeping your log splitter in top shape starts with regular inspections. You can spot problems early and avoid bigger issues later. Let’s break down what you should do before and after each use.

Visual Checks Before Use

A good visual inspection helps you catch trouble before it starts. Here’s a simple checklist you can follow every time you get ready to use your log splitter:

Look over the whole machine. Scan for cracks, bends, or rust on the main beam and frame.

Check all bolts, nuts, and fasteners. Make sure everything is tight and secure.

Inspect the wedge. See if there’s any damage or heavy wear.

For hydraulic models, look for leaks around the cylinder, pump, and hoses.

For kinetic models, check that the flywheel guard is locked in place. Make sure the drive area is clear of wood chips and dirt.

Tip: Your manufacturer’s manual will list specific inspection points for your log splitter. Keep it handy and refer to it often.

Doing a visual inspection before each use helps you catch problems early. You can avoid breakdowns and keep your log splitter working smoothly.

Detecting Leaks and Damage

Leaks and damage can slow you down or even stop your work. You need to know what to look for during your inspection. Here are some signs you should check:

Look for wear or damage on hoses, seals, and the hydraulic cylinder.

Listen for strange noises like grinding or squeaking. These sounds can mean something is wearing out inside.

Watch for leaking fluid. If you see any, fix it right away. Leaks often mean a seal or hose is failing.

Notice if your log splitter isn’t splitting wood as well as it used to. Less force or slower splitting can mean there’s internal wear.

The most common problems you’ll find during regular inspections include:

Loose fittings

Damaged hydraulic parts

If you spot any of these, stop using your log splitter until you fix the issue. Quick repairs keep your machine safe and strong.

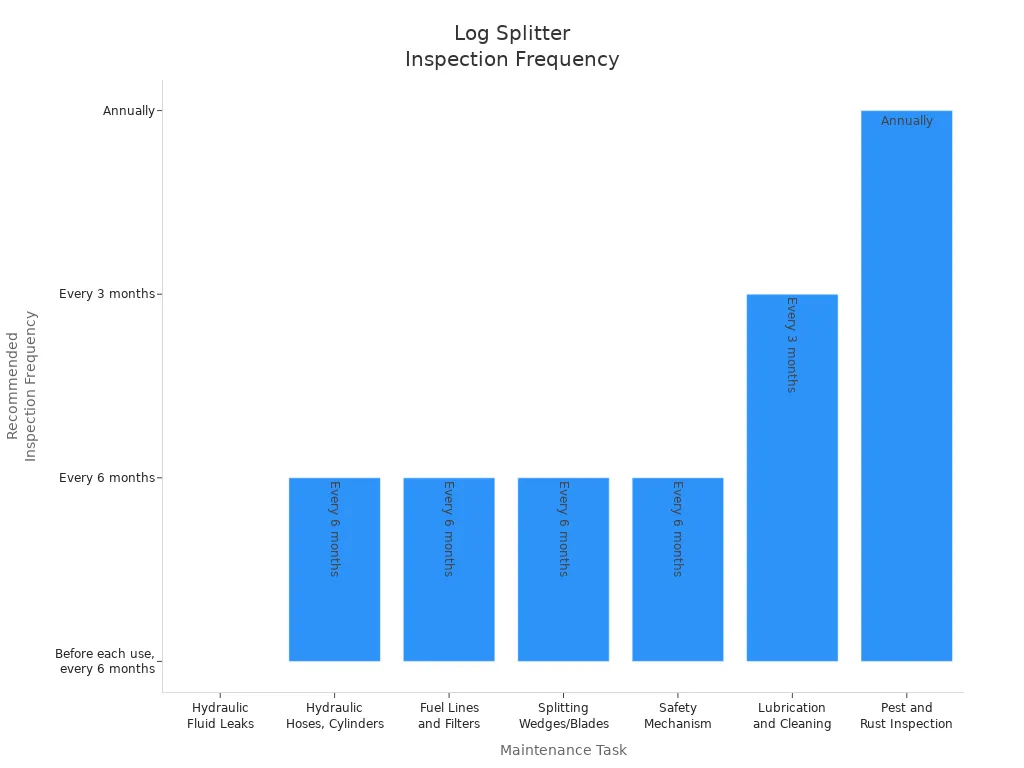

Inspection Frequency

How often should you inspect your log splitter? Regular inspections are key to good maintenance. Most manufacturers recommend checking for leaks and damage before each use and doing a deeper inspection every six months. Here’s a table to help you remember when to check each part:

Maintenance Issue / Task |

Common Problems Identified |

Inspection Frequency |

|---|---|---|

Hydraulic Fluid Leaks |

Leaks from hoses, fittings, seals |

Before each use, every 6 months |

Wear and Damage to Hydraulic Parts |

Cracks, leaks, wear signs |

Every 6 months |

Fuel Lines and Filters |

Clogging or damage |

Every 6 months |

Splitting Wedges/Blades |

Dullness or damage |

Every 6 months |

Safety Mechanism Functionality |

Safety guards not working |

Every 6 months |

Lubrication and Cleaning |

Lack of lubrication causing wear |

Every 3 months |

Pest and Rust Inspection |

Signs of rust or pest damage |

Annually |

You should always do a quick inspection before you start splitting wood. Every few months, take a closer look at all the parts. Once a year, check for rust and pests. If you keep up with regular inspections, you’ll catch problems early and extend the life of your log splitter.

Note: If you ever feel unsure about what to check, your manufacturer’s manual is your best friend. It gives you all the details for your specific model.

Regular inspections are a big part of log splitter maintenance. They help you spot trouble early, keep your machine safe, and make sure you get the best performance every time.

Hydraulic Log Splitter Maintenance

Taking care of your hydraulic log splitter is one of the best ways to keep it running strong. If you pay attention to hydraulic fluid management, you can avoid big problems and keep your machine working for years. Let’s look at how you can handle hydraulic fluid level check, fluid replacement, and spot issues before they get worse.

Checking Hydraulic Fluid Levels

You need to check the hydraulic fluid level before you start splitting wood. This simple step helps you avoid damage and keeps your log splitter working smoothly. Here’s how you can do it:

Use the dipstick on your hydraulic log splitter. Make sure you screw it in all the way before you read the level.

Look for a decal on the tank. It shows you the right way to check the fluid level.

Always check the fluid when the machine is cool and sitting on a flat surface.

If the fluid is low, top it off with the type recommended by your manufacturer.

Tip: Regular inspection and fluid checks help you catch problems early. If you use your log splitter often, check the fluid before each use.

Changing Fluid Properly

Changing the hydraulic fluid is a key part of maintenance. Old or dirty fluid can cause trouble for your hydraulic log splitter. Follow these steps to change the fluid safely:

Check your manual. It tells you how often to change the fluid and which type to use.

Find the drain plug. Put a container under it to catch the old fluid.

Remove the plug and let the fluid drain out completely.

Wipe around the plug and filter area to clean up any leftover fluid.

Replace the filter if your log splitter has one.

Pour new fluid into the reservoir. Don’t overfill it.

Run the log splitter for a few minutes. Check for leaks.

Dispose of the old fluid responsibly. Never pour it down the drain or on the ground.

Here’s a table to help you remember when to change the filter:

Maintenance Task |

Interval |

|---|---|

First filter change |

25 hours |

Subsequent filter change |

Every 100 hours or seasonally |

If you don’t use your log splitter much, you might only need to change the fluid every few years. Always check the fluid for dirt or cloudiness. If it looks clean, you’re good to go.

Note: Manufacturers recommend using the right hydraulic fluid for your log splitter. Common choices include tractor hydraulic oil, AW32 hydraulic oil, 10W hydraulic fluid, and Dexron transmission fluid. Automatic transmission fluid (ATF) is easy to spot if there’s a leak. Always follow your manual for the best results.

Signs of Fluid Issues

Spotting problems early can save you time and money. If your hydraulic log splitter starts acting strange, check for these signs:

Symptoms |

Explanation |

|---|---|

Vibration or shaking |

Low hydraulic oil level. Top off the fluid. |

Loss of driving force |

Air in the lines. Open the bleed valve and cycle the pressure plate. |

Slow ram movement |

Air in the system or low fluid levels. Bleed the system if needed. |

You should also look for leaks around hoses and seals. If you see fluid on the ground, fix the leak before using your log splitter again. Check the cooling system and make sure the heat exchanger works. Replace clogged filters and bleed the system to remove air. Test the hydraulic pump and pressure relief valves. Regular inspection and hydraulic fluid replacement keep your machine safe.

Alert: If you notice any of these problems, stop using your log splitter until you fix them. Quick action prevents bigger repairs and keeps your machine running well.

Hydraulic fluid management is a big part of log splitter maintenance. If you keep up with inspection, fluid checks, and replacement, you’ll get better performance and a longer life from your hydraulic log splitter.

Lubrication and Cleaning

Lubricating Moving Parts

You want your log splitter to run smoothly every time. Lubrication keeps the moving parts working well and helps prevent rust. Start by cleaning off wood chips, sap, and dirt after each use. Apply a high-quality lubricant made for heavy-duty outdoor equipment. Experts suggest using hydraulic oil designed for log splitters, like Forest Master Hydraulic Fluid. This oil protects against heat and corrosion. Lubricate the wedge, cylinder, bearings, and joints. Make sure you use a thin, even layer so you don’t attract extra dirt. Check hoses and connections for leaks. Change filters and hydraulic fluid as needed. Lubrication of moving parts is a key part of maintenance.

Part to Lubricate |

How Often |

Type of Lubricant |

|---|---|---|

Wedge |

Every use |

Hydraulic oil |

Cylinder |

Every use |

Hydraulic oil |

Bearings/Joints |

Every use |

Heavy-duty oil |

Cleaning After Each Use

Cleaning helps your log splitter last longer. Brush down the splitter after every use. Use mild cleaners, especially on the beam and wedges. Make sure the splitter is dry before you store it. Routine cleaning stops rust and keeps everything working well. Always check for damage while you clean. Cleaning and lubrication go hand in hand for good maintenance.

Brush off wood chips and dirt.

Wipe down all surfaces.

Use a mild cleaner for tough spots.

Dry the splitter to prevent rust.

Tip: Regular cleaning makes maintenance easier and helps you spot problems early.

Blade Sharpening Tips

A sharp blade makes splitting wood faster and safer. Check the wedge or blade every 50 to 100 hours. If you split hardwood or use your log splitter often, check more often. Sharpen the blade with a file or grinder if it feels dull. Blade care is part of good maintenance and keeps your log splitter working its best.

Replacing Parts and Repairs

Spotting Worn Components

You want your log splitter to work safely and efficiently. Regular maintenance helps you spot worn parts before they cause trouble. Look for cracks, rust, or bent metal on the frame. Check the wedge for chips or dull edges. Watch for leaking hydraulic fluid or loose hoses. If you notice slow splitting or strange noises, these can signal a problem. Always inspect the safety mechanism check area to make sure everything works as it should. Worn parts can put your safety at risk, so never ignore these signs.

When to Replace or Repair

Sometimes you can fix a problem with a simple repair. Other times, you need to replace a part. Here’s how you can decide:

If you feel unsure about safety, call an expert.

Check your warranty before you start. Some repairs must be done by certified pros.

If the same issue keeps coming back, get a professional diagnosis.

Some repairs need special tools you might not have.

Timely repairs keep your log splitter running and help you avoid bigger problems later. Always use the right parts for your machine.

DIY vs. Professional Help

You might want to fix your log splitter yourself. DIY repairs can save money and help you learn new skills. You get to choose when and how to do the work. Many people feel proud after a successful repair. But DIY repairs can take more time and may not last as long as professional work. Mistakes can also cause safety problems.

Professional repairs offer expert help and often come with a warranty. You can relax while someone else does the work. Pros have the right tools and know how to handle tough jobs. However, professional service costs more and you might have to wait for an appointment. Always wear safety gear when working on your log splitter, and never skip steps that protect your safety.

Storage and Protection

Storing in a Dry Place

You want your log splitter to last a long time. Pick a dry spot for storage. Wet places can make metal parts rusty and weak. If you keep it outside, put it on something raised. This keeps water away from the machine. A shed or garage is the best place to store it. Make sure the area is clean and has no pests. Good storage helps your log splitter stay strong.

Weatherproofing Your Log Splitter

Rain and snow can hurt your log splitter. Use a strong tarp or fitted cover to protect it. This keeps water and dirt out. You can use sealants to block water from cracks. Here are some sealant choices:

Sealant Type |

Key Features |

|---|---|

Silicone-based |

Stays flexible and strong, great for sealing cracks. |

Acrylic-based |

Easy to use, sticks well to wood, keeps out moisture. |

Epoxy-based |

Very tough, stops water from getting in. |

Check your log splitter for cracks or bent parts often. Put on more sealant when you need it. Use wood preservatives to stop bugs and rot. Weatherproofing helps your log splitter last longer.

Seasonal Storage Advice

When seasons change, get your log splitter ready for storage. Clean and oil all moving parts before you put it away. If you can, store it standing up. This saves space and protects the hydraulic cylinder. Always keep it covered and dry. Good care and smart storage keep your log splitter ready for next year.

Tip: Clean and oil your log splitter before storing it. This stops rust and keeps it working well.

Monitor Performance

Tracking Efficiency

You want your log splitter to work its best every time. Tracking performance helps you spot problems early. Keep a simple log of how many logs you split each session. Write down how long it takes and if you notice anything strange. If you see a drop in performance, check your maintenance routine. Cleaning and lubrication play a big role in keeping your log splitter strong. Good performance monitoring helps you plan repairs and avoid downtime.

Session |

Logs Split |

Time Taken |

Notes on Performance |

|---|---|---|---|

1 |

50 |

30 min |

Smooth operation |

2 |

40 |

35 min |

Wedge moved slowly |

Early Warning Signs

You need to watch for signs that your log splitter is not working right. Early warning signs help you catch issues before they get worse. Here are some things to look for:

Hydraulic fluid leaks near the reservoir or hoses.

Cylinder rods move slowly or not at all.

The wedge moves strangely or the piston does not work.

The control valve handle is hard to move or feels stuck.

The engine stalls, surges, or shuts off.

Hydraulic fluid looks foamy.

The machine gets too hot and shuts down by itself.

The circuit breaker trips.

If you see any of these, stop and check your log splitter. Quick maintenance and cleaning can prevent bigger problems.

Troubleshooting Basics

When performance drops, you need to troubleshoot. Start with cleaning and checking for leaks. Look at the hydraulic fluid level and see if it needs topping off. Make sure all safety features work. If you find a problem, decide if you can repair it yourself or need help. Always follow your maintenance schedule. Good performance monitoring and fast repair keep your log splitter safe and strong.

Tip: Write down any changes in performance. This helps you spot patterns and plan maintenance before you need a big repair.

You can help your log splitter last a long time by doing easy maintenance. Try these steps:

Look at your log splitter before and after you use it.

Clean parts that move and add oil to them.

Check the hydraulic fluid often to make sure it is full.

Pick a good place to store your log splitter in every season.

Use a checklist to remember what to do for care and storage.

Tip: Your manual gives you advice for taking care of and storing your log splitter.

FAQ

How often should you change the hydraulic fluid?

You should change the hydraulic fluid every 100 hours of use or once each season. Always check your manual for the best advice.

What should you do if your log splitter won't start?

First, check the fuel and oil levels. Make sure the battery works. Inspect the spark plug. If it still won't start, ask a professional for help.

Can you split wet wood with your log splitter?

You can split wet wood, but it may take more effort. Wet wood can stick to the wedge and slow down your work.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.