Ever tried to split a big log and wondered if you chose the right log splitter? Picking the right features for your log splitter makes your work safer and easier. Look at the table below to see how each feature affects how well and safely you can split logs:

|

Feature/Parameter |

Impact on Efficiency and Safety |

|---|---|

|

Shaft Diameter |

A bigger shaft keeps the SuperHandy 25 Ton Gas Log Splitter steady for large logs. |

|

RPM Range |

The right RPM stops strain and helps the Landworks 20-Ton Log Splitter work faster. |

|

Flow Rate (GPM) |

More GPM means you can split thick logs faster. |

|

Pressure (PSI) |

The right PSI splits hard wood without making the log splitter work too hard. |

|

Pump Type |

Gear, piston, or vane pumps work best for different jobs and log sizes. |

|

Two-Stage Pumps |

You can switch between speed and power for different kinds of wood. |

|

Material |

Cast iron and steel make the splitter last longer and easier to move. |

|

Shaft-Pump Compatibility |

The right match stops damage and makes the splitter safer and last longer. |

Before you pick a log splitter, think about your wood, the size of your logs, and how often you will use it.

Key Takeaways

-

Choose a log splitter that matches your wood type and log size to work safely and efficiently.

-

Pick the right power source and tonnage based on how often you split wood and the size of your logs.

-

Always follow safety rules and maintain your splitter to keep it working well and avoid injuries.

Top Considerations for Choosing a Log Splitter

Wood Type and Log Size

When you start looking for a log splitter, you need to think about the type of wood you’ll be splitting and the size of the logs. Some woods are soft, like pine or cedar. Others, like oak or hickory, are much harder. Hardwoods need more splitting force. If you plan to split large, tough logs, you’ll want a stronger machine.

Check out this table to see how different splitter types match up with wood properties and log sizes:

|

Splitter Type |

Suitable Wood Properties |

Log Size Range |

Splitting Force |

Usage Context |

|---|---|---|---|---|

|

Horizontal Splitters |

Softer woods, smaller to medium logs |

Up to ~250 mm diameter |

Lower splitting force |

Residential use, lighter splitting |

|

Vertical Splitters |

Harder woods, large, heavy, knotty logs |

Up to ~600 mm diameter |

Higher splitting force |

Commercial use, large volume splitting |

You also need to think about how you’ll handle the logs. Horizontal splitters work best for smaller logs, but you have to lift them onto the machine. Vertical splitters let you roll big logs into place, which saves your back.

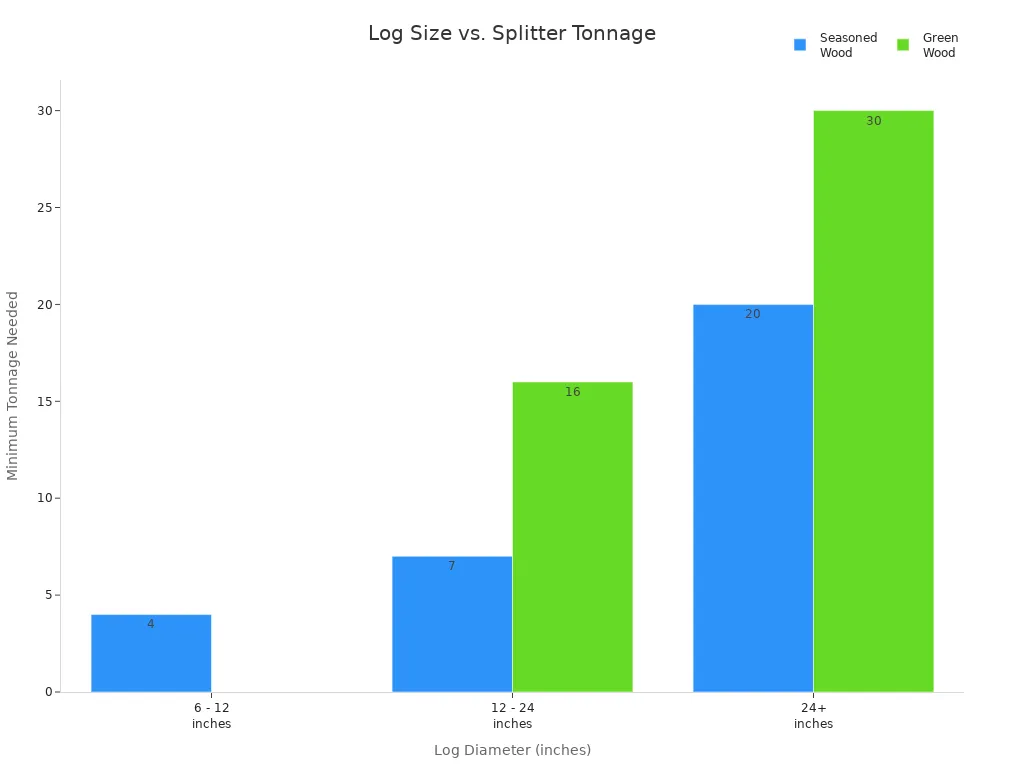

Tip: If you mostly split firewood from fallen trees, check if the wood is green or seasoned. Green wood is harder to split and needs more power.

Usage Frequency and Project Size

Ask yourself how often you plan to use your log splitter. If you only split wood a few times a year, you might not need a heavy-duty model. For regular use or big projects, a more powerful splitter will save you time and effort.

Here’s a quick look at average log sizes and what you’ll need:

|

Project Type |

Typical Log Diameter |

Recommended Tonnage |

|---|---|---|

|

Residential |

Up to 24 inches |

7-16 tons |

|

Commercial |

28-36 inches |

20-40 tons |

Manual splitters handle logs up to 12-18 inches. Electric splitters work for logs up to 24 inches. Gas-powered splitters can tackle logs up to 36 inches. If you rent a splitter, most units are around 26 tons, which is enough for most home projects.

Note: If you plan to split wood for a whole season or for a business, choose a log splitter with a higher tonnage and faster cycle speed.

Tonnage and Power Source

Tonnage means the amount of force your log splitter can deliver. The right tonnage depends on the size of the logs and the type of wood. Hardwoods like oak need more force than softwoods like pine. For example, a 6-inch hardwood log may need 10 tons, while a softwood log of the same size only needs 4 tons. Large hardwood logs, especially if they are green, can require up to 37 tons.

Here’s a table to help you match tonnage to your wood splitting needs:

|

Wood Type |

Log Diameter |

Recommended Tonnage |

|---|---|---|

|

Hardwood (elm, hickory) |

6 inches |

10 tons or more |

|

Softwood (pine) |

6 inches |

4 tons |

|

Hardwood (oak) |

24 inches |

30-37 tons |

|

Softwood |

Larger diameters |

Less than hardwood |

Now, think about the power source. Manual splitters are affordable and portable, but you need muscle power. Electric splitters are quiet and easy to maintain. They work well for small jobs. Gas-powered splitters are strong and mobile. They need more care and regular refueling, but they handle big logs and tough wood.

|

Power Source |

Performance Characteristics |

Maintenance Needs |

|---|---|---|

|

Manual |

Needs physical effort; portable; less powerful |

Minimal maintenance; no fuel or electricity needed |

|

Electric |

Quiet; easy to maintain; for smaller tasks |

Regular cleaning and lubrication |

|

Gas-Powered |

Powerful; for heavy-duty use; mobile |

Refueling, engine care, cleaning, inspection |

Tip: If you want to save money, look for used log splitters online or at local dealers. You can also check out payment plans from stores like Abunda, which offer monthly payments and rent-to-own options.

When you think about the top considerations for choosing a log splitter, remember to match the machine to your wood splitting needs, the type of wood you’ll be splitting, and the size of the logs. This way, you’ll get the right tool for your job and avoid wasting time or money.

Types of Log Splitters and Key Features

Manual, Electric, and Gas Log Splitters

When you look at the types of log splitters, you’ll see three main options: manual, electric, and gas-powered. Each one works best for different jobs and users. Manual splitters use your strength and don’t need fuel or electricity. They’re quiet, portable, and great for small jobs. Electric log splitters plug into a regular outlet. They’re easy to use, quiet, and perfect for splitting small to medium logs at home. Gas-powered log splitters pack the most power. You can use them anywhere, and they handle big, tough logs. They’re louder and need more care, but they’re the top choice for heavy-duty work.

Here’s a quick table to help you compare:

|

Feature |

Manual Splitters |

Electric Log Splitters |

Gas-Powered Log Splitters |

|---|---|---|---|

|

Power |

Low (your effort) |

Moderate |

High |

|

Operation |

No fuel/electricity |

Needs outlet |

Uses engine, portable |

|

Splitting Capacity |

Small jobs |

Small to medium logs |

Large, tough logs |

|

Noise |

Quiet |

Quiet |

Loud |

|

Maintenance |

Minimal |

Low |

Regular engine care |

|

Cost |

Low |

Affordable |

Higher upfront cost |

Log Splitter Features

You want a log splitter that makes your job easier and safer. Some important log splitter features include splitting force, cycle speed, portability, safety, and maintenance. Splitting force tells you how much power the machine has. Cycle speed means how fast it splits each log. Wheels and handles make it easy to move your splitter. Safety features like guards and two-handed controls help keep you safe. Electric log splitters need less maintenance than gas models. Gas splitters need oil changes and engine checks, while electric ones just need cleaning and a little oil.

Always wear gloves and safety glasses when you use any log splitter. Keep kids and pets away from your work area.

Matching Splitter Types to Needs

Picking the right log splitter depends on your wood and your project. For soft woods like pine, a smaller electric log splitter works well. If you have big, hard logs like oak, you’ll need a gas-powered log splitter with more force. For heavy-duty jobs or lots of wood, choose a splitter with higher tonnage. If you only split wood sometimes, a manual or electric model saves money and space. Think about how often you’ll use it, how big your logs are, and where you’ll work. That way, you’ll get the best tool for your needs.

How to Choose the Right Log Splitter

Common Mistakes to Avoid

You want to choose the right log splitter, but it’s easy to make mistakes. Many people pick a splitter that doesn’t match their wood type or log size. This can waste time and damage your tool. Some forget to keep the wedge sharp or ignore oil leaks in the hydraulic system. Others use logs that are too big or wet, which makes splitting tough and can hurt the machine. Safety matters too. If you skip wearing gloves or don’t secure the log, you risk injury.

Here’s a quick table to help you spot common mistakes and how to avoid them:

|

Common Mistake |

Potential Consequences |

Best Practice |

|---|---|---|

|

Choosing the wrong splitter type |

Inefficient splitting, tool damage |

Match splitter to wood type and log size |

|

Neglecting maintenance |

Rust, dull blades, mechanical failure |

Clean, lubricate, and store properly |

|

Ignoring safety protocols |

Injury, unstable splits |

Use PPE, secure logs, maintain proper stance |

|

Poor splitting technique |

Excessive wear, wasted effort |

Apply controlled force, adjust log position |

Tip: Always check your log splitter for leaks, dull blades, and loose parts before you start.

Final Tips for Selection

You want to choose the right log splitter for your needs. Start by thinking about your log size and how often you split wood. Pick a power source that fits your work area. Electric splitters work well for small jobs. Gas splitters handle bigger logs. Look for a model with enough splitting force for your wood. Vertical splitters make it easier to handle heavy logs. Horizontal splitters work best for smaller pieces.

Before you buy, check reviews and customer feedback. Log splitter reviews can show you what works and what doesn’t. Compare brands, warranty options, and cycle speed. Test used splitters if you can. Make sure the machine runs smoothly and feels safe. Ask about maintenance records. Reliable brands last longer and offer better support.

Remember: Choose the right log splitter by matching its features to your project. Don’t rush. Take your time and compare options.

Choosing the right log splitter starts with knowing your wood type, log size, and how often you split. Check the chart below to match power to your needs. Look for features that boost safety and make moving the machine easy. Take time to compare options before you buy!

FAQ

What size logs can most splitters handle?

You can split logs up to 24 inches with most home models. Commercial splitters work with logs up to 36 inches.

How often should you maintain your splitter?

You should check for leaks, clean the wedge, and lubricate moving parts after every use. Regular care keeps your machine running smoothly.

Can you use a splitter indoors?

You can use electric splitters indoors if you have good ventilation. Gas models need outdoor space because of exhaust fumes.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.