A wood chipper lets you change big branches into small chips. It uses sharp blades that spin fast. You put wood into the chipper’s chute. Rollers or a drum pull the wood to the blades. This makes cleaning up quick and easy. Many people use a chipper for yard work. It helps with tree removal and land clearing. Landscapers and homeowners use the chips as mulch. Mulch keeps soil wet and stops weeds from growing. Machines like the Landworks Compact Wood Chipper help with green waste. The Wood Chipper Pro also helps after land clearing or pruning. These machines make cleanup simple.

Key Takeaways

-

A wood chipper cuts branches and wood waste into small chips. You can use these chips for mulch or compost. This helps you clean your yard faster and easier.

-

Pick a chipper that fits your yard size and wood type. Think about how often you will use it. There are gas, electric, and tractor-powered models. Each has different power and capacity.

-

Safety is very important when you use a chipper. Always wear protective gear. Keep your hands away from moving parts. Follow the instructions from the manufacturer to stay safe.

-

Regular maintenance helps your chipper last longer. Sharpen the blades, check the oil, and clean the machine often. This makes your chipper work better.

-

Wood chippers are not the same as shredders. Chippers cut thick branches and make chips that look the same. Shredders work best with leaves and soft garden waste.

Wood Chipper

Definition

A wood chipper is a machine that helps you turn branches, limbs, and other wood waste into small pieces called chips. You can use a wood chipper in your yard, on a farm, or at a job site. Many people call it a chipper or even a tree chipper when it handles large branches. This tool makes cleanup easier and helps you recycle wood into useful mulch or compost.

There are different types of wood chippers. Each type has a special design and use. Here is a table to help you see the main types and how they work:

|

Type Category |

Subtype |

Design Characteristics & Usage |

|---|---|---|

|

Power Source |

Gas-Powered |

More powerful, good for large branches and frequent use; louder; needs more care; portable anywhere |

|

|

Electric |

Smaller, quieter, eco-friendly; best for light yard work; less powerful; needs a power outlet |

|

|

PTO (Power Take-Off) |

Tractor-powered; used for heavy-duty jobs; most powerful type |

|

Mechanical Design |

Disc Chippers |

Blades on a spinning disc; lighter; fast feed; best for small branches; may miss flexible small branches |

|

|

Drum Chippers |

Spinning drum feeds and chips wood; handles large, tough wood and fibrous material; compact and reliable |

|

Additional Types |

Wood Shredders |

Smaller; semi-blunt blades; best for leaves and small debris; makes mulch and compost |

|

|

Chipper Shredders |

Combines shredding and chipping functions |

Tip: Choose a chipper that matches the size of your yard and the type of wood you need to chip.

Main Parts

Every wood chipper has several important parts. Each part has a job to do. Here is a table that shows the main parts and what they do:

|

Component |

Function |

|---|---|

|

Infeed Chute |

Guides branches and wood into the chipper safely |

|

Infeed System |

Pulls material from the chute into the chipping area, often with rollers or gravity |

|

Chipping Mechanism |

Cuts wood into chips; uses a drum or disc with sharp blades |

|

Discharge Chute |

Sends the chips out of the machine; you can often adjust the direction |

|

Engine/Power Source |

Runs the chipper; can be gas, electric, or PTO (tractor-powered) |

You may also find other parts like a gearbox, belts, pulleys, and separate chutes for different outputs. Some chippers use hydraulic rollers to pull in branches. Others use gravity feed for smaller jobs.

How It Works

A wood chipper works in a few simple steps. Here is how you use it to turn branches into chips:

-

You feed branches or wood into the infeed chute. The chute keeps your hands safe.

-

The infeed system, often with rollers, pulls the wood into the chipper.

-

Inside, sharp blades on a spinning drum or disc cut the wood into small chips.

-

The spinning motion creates force. This force pushes the chips out through the discharge chute.

-

The discharge chute sends the chips to a pile or a bag for easy collection.

-

Hydraulic rollers can make feeding easier. They pull in branches and reduce your effort.

-

The cutting mechanism slices and breaks down the wood quickly.

-

The discharge system lets you control where the chips go.

Note: Always follow safety rules when using a chipper. Keep hands and tools away from moving parts.

A wood chipper helps you turn waste into useful chips for mulch or compost. You can pick a chipper that fits your needs, from small electric models for light work to large gas or PTO chippers for big jobs.

Uses

Yard Cleanup

A chipper helps you clean your yard faster. Storms or pruning leave branches and wood waste. The chipper turns them into small chips. This saves you lots of time. Picking up debris by hand takes longer. Using a chipper can cut weeks of work to days. Machines can chip thick branches easily. They work for hours without stopping. You can reuse the chips as mulch. You can also collect chips for other projects. Modern chippers have safety features. These help you work with less risk.

Tip: A chipper works better than cleaning up by hand for big piles.

Mulch and Biomass

Chippers let you recycle wood waste. You feed branches and leaves into the chipper. It breaks them down into wood chips. You can use these chips as mulch in your garden. Mulch keeps soil wet and stops weeds. It also helps soil health as it breaks down. Some people use wood chips for composting. They mix chips with other waste to make rich soil. In some places, wood chips become biomass fuel. This means chips are used to make energy. Using chips for mulch or fuel keeps waste out of landfills. It helps the environment by lowering greenhouse gases.

-

Ways to use wood chips:

-

Mulch for gardens and flower beds

-

Compost material

-

Renewable energy (biomass fuel)

-

Commercial Applications

Many businesses use chippers to manage wood waste. In forestry, workers chip logs and branches after logging. Landscaping companies chip tree trimmings and green waste. City teams use chippers to recycle urban wood waste. This helps lower disposal costs. Biomass plants use wood chips for fuel. These uses turn wood waste into useful products. They also support eco-friendly practices.

-

Industries that use chippers:

-

Forestry and logging

-

Landscaping and urban forestry

-

Biomass energy production

-

Note: Turning wood waste into chips helps reduce landfill use. It also supports sustainability in your community.

Key Features

When you pick a wood chipper, look at some main features. These features change how well the chipper works. They also affect how safe and easy it is to use. The best chipper helps you turn branches into chips fast and safely.

Power Source

The power source is a very important part of any chipper. You can choose gas-powered, electric (with a cord or battery), or PTO models. Each type has good and bad points.

|

Feature |

Gas-Powered Wood Chipper |

Electric Wood Chipper (Corded) |

Electric Wood Chipper (Cordless) |

|---|---|---|---|

|

Power Source |

Gasoline engine (6-15 hp) |

Mains electricity (15 amps) |

Rechargeable battery |

|

Chipping Capacity |

High (3+ inches diameter) |

Moderate (up to 1.75 inches) |

Lower (up to 1.5 inches) |

|

Portability |

Excellent |

Limited by cord |

Excellent (battery range) |

|

Noise Level |

Loud |

Quieter |

Quietest |

|

Emissions |

Yes |

None |

None |

|

Maintenance |

Regular |

Minimal |

Minimal |

|

Weight |

Heavier |

Lighter |

Generally lighter |

|

Starting |

Pull-start or electric |

Push-button |

Push-button |

|

Typical Use |

Heavy-duty, large properties |

Small yards, light debris |

Light tasks, convenience |

|

Initial Cost |

Moderate to high |

Lower to moderate |

Moderate to high |

Gas-powered chippers are strong and work anywhere. You can chip big branches and work for a long time. These machines need more care, like oil and fuel checks. Electric chippers are quieter and easy to start. You just press a button. Corded chippers need an outlet, so you must stay close to your house. Cordless chippers use batteries, so you can move them, but they are best for small jobs. PTO chippers hook up to tractors and do the biggest jobs, like clearing land or working on farms.

Tip: Pick a power source that fits your yard and the wood you need to chip.

Capacity

Capacity shows how much wood the chipper can handle at once. It also tells you the biggest branch size you can put in. If you have big branches or lots of sticks, you need a chipper with more capacity.

|

Capacity Type |

Typical Feed Opening Size |

Suitable Use Case |

Mobility & Handling |

|---|---|---|---|

|

Small/Residential |

Around 12 inches |

Small brush and limbs, residential use |

Light enough to haul with a small pickup |

|

Medium (6-inch chip) |

12 inches (minimum) |

Starter machine, effective for smaller brush, two-person feeding possible |

Portable, manageable in urban and some rural areas |

|

Large/Commercial |

Larger than 12 inches |

Larger brush, commercial tree removal |

Requires more space, often used in flat or accessible areas |

A small chipper is good for home gardens and light yard work. You can chip small branches and make mulch. Medium chippers can handle thicker branches and are good for bigger yards. Large chippers can chip huge logs and lots of debris. These are best for tree services or city workers. Always check the feed size and engine power before you buy. If you try to chip wood that is too big, you might jam the chipper or break the blades.

Safety Features

Safety is very important when you use a chipper. New chippers have many safety features to keep you safe.

-

Automatic feed systems keep your hands away from the blades.

-

Emergency stop buttons let you turn off the chipper fast if needed.

-

Shields cover moving parts and stop chips from flying out.

-

Some chippers use closed drum knife systems for better safety.

-

Some models have safety gates that sense metal in gloves and stop the feed if you get too close.

"A chipper safety gate can sense special gloves and stop the machine if your hand gets too close. This helps prevent serious injuries and keeps you safe while you work."

You should always wear gloves and eye protection. Look for chippers with safety marks like CE, UL, and ISO 9001. These show the chipper meets strict safety and quality rules.

Portability

Portability means how easy it is to move your chipper. If you have a big yard or work in different places, you need a chipper that is easy to move.

-

Small models fit in tight spaces and are easy to store.

-

Workers often need portable chippers to move between jobs.

-

If you only use the chipper in one spot, portability is not as important.

A portable chipper saves you time and work. You can bring it right to the pile of branches instead of dragging sticks across your yard. For city workers or landscapers, portability is very important.

Note: Always check the weight and size before you buy. Make sure you can move it safely and store it when you are done.

When you look at features like power source, capacity, safety, and portability, you can find the best chipper for you. These features help you work faster, stay safe, and use your chipper well. The right chipper makes yard work easy and safe. You will also get lots of chips for mulch or compost.

Wood Chipper vs Shredder

Differences

You may wonder how a wood chipper and a wood shredder differ. Each machine has a special job and design. A wood chipper uses sharp blades on a disc or drum to cut thick branches into uniform chips. You feed large wood pieces into a big hopper, and the chipper turns them into chips for mulch or biomass fuel. Chippers need more power and regular blade care.

A wood shredder works differently. It uses hammers, knives, or open blades to break down smaller branches, leaves, and green waste. You get finer mulch or sawdust, which helps with composting and soil moisture. Shredders handle a wider range of materials, including hedge clippings and brambles. They often have more than one chute and can process softer, moist debris without clogging. Shredders cost less and suit smaller gardens or less frequent use.

Tip: Chippers work best for thick, woody debris. Shredders handle mixed garden waste and produce finer mulch.

Here is a quick comparison:

|

Feature |

Wood Chipper |

Wood Shredder |

|---|---|---|

|

Best for |

Large branches, logs |

Leaves, twigs, green waste |

|

Output |

Uniform wood chips |

Fine mulch or sawdust |

|

Power |

High |

Moderate |

|

Maintenance |

Regular blade care |

Less frequent |

|

Cost |

Higher |

Lower |

Which to Choose

You need to think about your yard and the type of debris you have. If you have a big yard with lots of thick branches, a wood chipper will help you clear it fast. You can use the chips for landscaping or fuel. If you have a small garden with leaves, hedge clippings, and soft waste, a wood shredder is a better choice. It makes fine mulch for compost and soil health.

Consider these points before you decide:

-

Yard size: Large yards need powerful machines. Small yards do well with compact models.

-

Type of debris: Thick wood calls for a chipper. Mixed or soft waste fits a shredder.

-

Frequency of use: If you chip often, choose a durable, high-power machine. For light, occasional use, pick a chipper shredder or a small shredder.

Note: A chipper shredder combines both functions. You can handle branches and garden waste with one tool.

Choose the machine that matches your needs. You will save time and get the best results for your yard.

Safety and Maintenance

Safety Tips

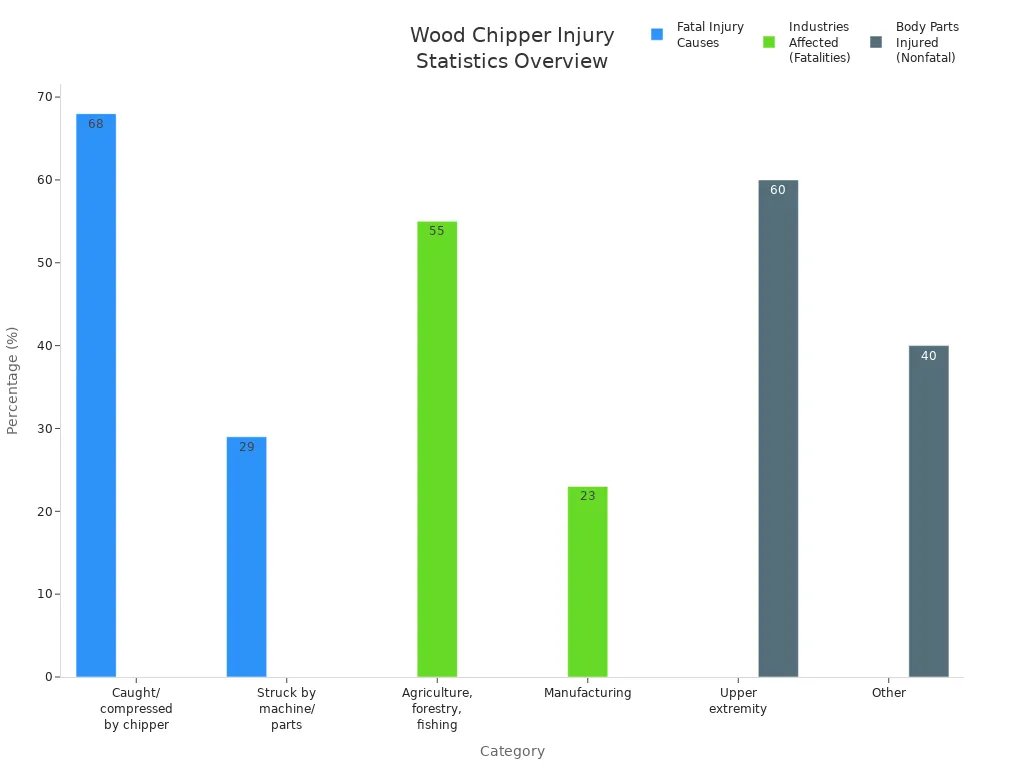

You should always be careful when using a chipper. Accidents happen if you do not follow safety rules. Most injuries happen when people get caught in the feed system. Some get hurt by flying wood chips or by handling wood the wrong way. Every year, about 1,200 people go to the hospital because of chipper accidents. Many of these injuries hurt hands, arms, or eyes.

To stay safe, follow these tips:

-

Stand beside the feed chute, not in front.

-

Put branches in butt-end first.

-

Use push sticks or long branches to feed wood. Never use your hands.

-

Wear safety glasses, ear protection, gloves, a hard hat, and boots.

-

Keep the area clean. Do not let kids or pets near.

-

Check wood for rocks or metal before feeding it.

-

Never reach into the hopper. Use tools to clear jams after turning off the chipper.

-

Turn off and unplug the chipper before fixing or clearing jams.

-

Stay focused and do not get distracted.

-

Handle fuel safely. Turn off the engine, let it cool, and refuel outside.

-

Only trained people should use the chipper.

Always read and follow the manufacturer's safety instructions. Do not remove safety guards or devices.

Maintenance

Taking care of your chipper helps it work well and keeps you safe. If you keep up with maintenance, your chipper can last up to 15 years. If you ignore it, it may only last five years or less. Check and service your chipper often, especially if you use it a lot.

Here is an easy maintenance schedule:

|

Maintenance Task |

Frequency |

|---|---|

|

Check engine oil level |

Before each use |

|

Inspect general equipment condition |

Before each use |

|

Check flywheel turns freely |

Before each use |

|

Inspect knife for damage |

Before each use |

|

Sharpen knife and wear plate |

Every 8-10 hours |

|

Lubricate bearings and moving parts |

Every 8-10 hours |

|

Clean engine exterior and cooling fans |

Every 8-10 hours |

|

Inspect or replace drive belt |

Every 40 hours |

|

Change engine oil and filter |

Every 40 hours |

|

Inspect or replace spark plug |

Every 40 hours |

|

Inspect or replace air filter |

Every 40 hours |

Do more maintenance if you work in dusty or dirty places. Always turn off the chipper and wait for it to stop before fixing anything. Use only parts approved by the manufacturer. Dull blades make work slower and use more fuel. Replace or sharpen blades if chips look uneven or the engine struggles. Clean out wood chips and debris after each use to stop jams and damage.

Keeping your chipper clean and following safety rules helps it last longer and work better.

A chipper lets you turn yard waste into mulch or compost. Pick a chipper that fits your yard size and waste type. Make sure it has the right power for your needs. Look for features like how it feeds wood, if it is easy to move, and if it is safe.

-

Make sure your chipper works with your tools and can handle your yard waste.

-

Think about how much money you want to spend and how often you will use it.

-

Always wear safety gear and follow care tips.

For the best results, look at different models and ask experts or landscapers for help before you buy.

FAQ

How do you know what size wood chipper you need?

You should check the largest branch you want to chip. Pick a chipper with a feed opening at least one inch bigger than your thickest branch. This helps you avoid jams and keeps the machine running smoothly.

Can you put wet wood or leaves in a wood chipper?

Most chippers handle dry wood best. Wet wood or leaves may clog the machine. If you want to chip wet material, use a chipper-shredder designed for mixed yard waste.

How often should you sharpen the blades?

You should check the blades after every use. Sharpen them every 8 to 10 hours of chipping. Dull blades make the chipper work harder and can cause jams.

What safety gear should you wear when using a wood chipper?

Always wear safety glasses, gloves, ear protection, and sturdy boots. A hard hat and close-fitting clothes help protect you from flying chips and moving parts.

Can you rent a wood chipper instead of buying one?

Yes, you can rent a chipper from most hardware stores or equipment rental companies. Renting works well if you only need a chipper for a short time or for one big project.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.