A wood chipper is a machine that turns branches, leaves, and small logs into wood chips. The chipper uses sharp knives and a spinning impeller to break down material quickly. Many homeowners use a chipper for yard cleanup, recycling old branches, or creating mulch. Some prefer a Wood Chipper Mini for small jobs, while others choose a Wood Chipper Pro for bigger tasks. A Leaf Vacuum & Wood Chipper can handle leaves and twigs easily. Wood chips from a chipper help keep gardens healthy and neat.

Tip: Safety gear should always be worn when using a chipper.

Key Takeaways

-

A wood chipper can quickly change branches and yard waste into wood chips. These chips are good for mulch or garden paths.

-

There are different types of chippers. Some use electric power, and some use gas. Some have a drum, and some have a disc. Each type is good for small or big jobs. They also have different power and ways to move them.

-

Safety is very important. Always wear safety gear. Feed branches into the chipper slowly. Never put your hands in the chipper when it is on.

-

You need to take care of the chipper often. Sharpen the blades and clean it to keep it working well. This helps stop jams.

-

Pick the right chipper for your yard. Think about the size of branches, how much power you need, and what safety features it has.

What Is a Wood Chipper

Main Features

A wood chipper is a strong machine. It breaks branches, limbs, and trunks into small wood chips. Most wood chippers have knives that spin on a drum or disc. These knives turn very fast, between 1,000 and 2,000 RPM. Gas or petrol engines make the knives spin. The fast spinning helps the chipper work quickly. It saves time compared to chopping wood by hand.

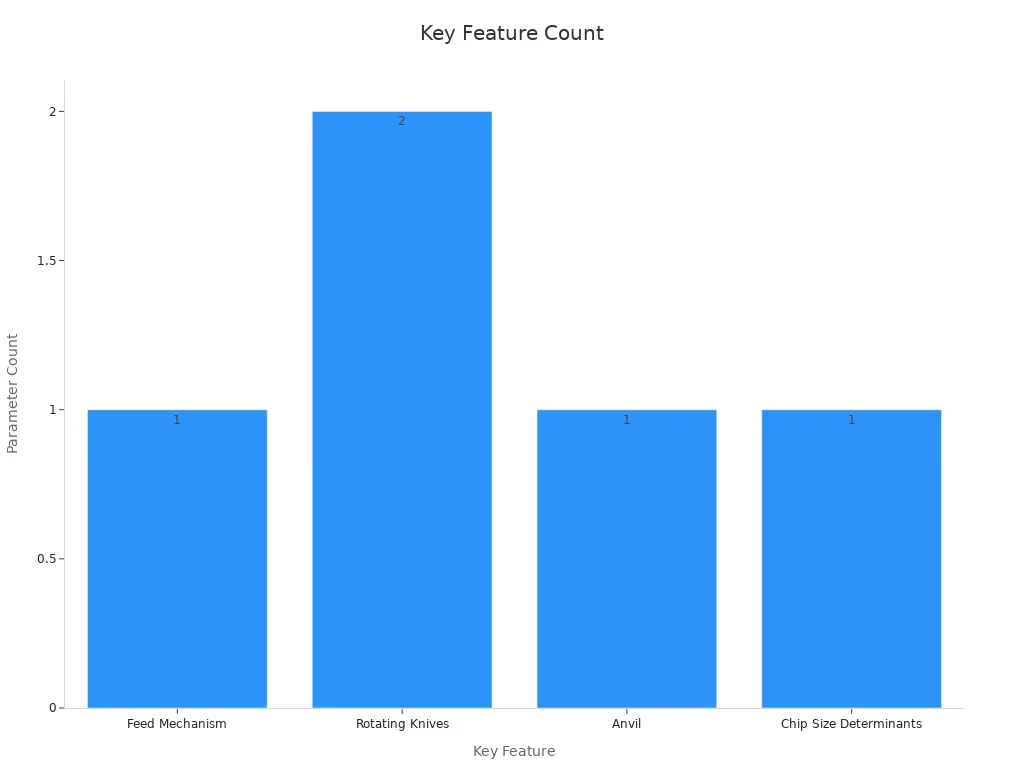

Key features you often see in a wood chipper are:

|

Key Feature |

Description |

|---|---|

|

Feed Mechanism |

Rollers or conveyors pull wood into the chipper. |

|

Rotating Knives |

Sharp blades cut wood into chips. |

|

Anvil |

A fixed part that helps the knives slice the wood. |

|

Discharge Chute |

Directs wood chips out of the machine. |

|

Mounting Type |

Some chippers are trailer-mounted, while others are self-propelled. |

|

Safety Features |

Shields, emergency stops, and safety gear requirements protect the operator. |

The size of the wood chips depends on two things. It depends on how far apart the knives and anvil are. It also depends on how fast the wood goes in. Some chippers, like helical models, let you change the infeed angle. This can make the chips longer or shorter. Studies show helical blades make more chips in the right size range than other blades.

Note: Always wear gloves, long pants, non-slip shoes, and ear protection when using a chipper.

Common Uses

People use wood chippers for many jobs in the yard and garden. The main job is turning branches and tree limbs into wood chips for mulch. Mulch helps keep soil wet and stops weeds from growing. Homeowners also use a chipper shredder to clean up after storms or pruning.

Wood chippers come in many sizes and power levels. A landscaping chipper makes wood chips between 0.75 and 2 inches. These chips are good for garden beds. Tractor PTO-driven chippers can process up to 65 cubic yards of material each hour. This is helpful for big yard cleanups. Some industrial chippers, like the CBI Magnum Force 6800CT, can handle up to 200 tons of wood waste per hour.

A tree chipper can also recycle wood. It turns old branches into useful chips. Many gardeners use wood chips to cover paths or playgrounds. Chippers help cut down on garden waste sent to landfills. This makes them a good choice for the environment.

How a Wood Chipper Works

Chipping Process

A wood chipper turns branches and logs into small wood chips through a simple but powerful process. First, the user feeds wood into a hopper. Draw-in rollers grip the wood and pull it toward the spinning disc or drum inside the machine. The disc or drum spins at high speeds, often between 1,000 and 2,000 revolutions per minute. Sharp cutters mounted on the disc or drum slice the wood into chips as it moves past.

The feeding process matters for both safety and efficiency. Most wood chippers use two rollers with special grips to hold and move the wood. These rollers can feed wood straight in or at an angle, depending on the design. The control unit inside the machine uses sensors to watch the speed of the rollers and the disc. It can adjust the feeding speed to keep the chip size even and prevent jams.

Proper feeding helps avoid clogs. For example, the CJ 601E wood chipper works best when users follow the recommended branch size. Oversized branches can cause clogs, but the machine makes it easy to clear them. Users just unplug the chipper and open a knob to remove stuck material. This design helps keep the output of wood chips steady and reduces downtime.

The chipping process also depends on the type of wood. Hard, dense wood needs more power and sharper blades. Softer wood moves through faster. The machine’s horsepower and blade sharpness both play a role in how well it handles different materials.

Tip: Always check the maximum branch diameter before feeding wood into the chipper. This keeps the machine running smoothly and prevents jams.

Key Components

A wood chipper uses several key parts to turn wood into chips. Each part has a special job in the process.

|

Component/Aspect |

Description |

|---|---|

|

Rotor Disc or Drum |

Spins at high speed. Holds the cutters that chip the wood. |

|

Cutters (Knives) |

Sharp blades mounted on the disc or drum. Slice wood into chips. |

|

Draw-in Rollers |

Grip and feed wood toward the cutters. Can be set straight or at an angle. |

|

Hopper |

The opening where users place branches and logs. |

|

Control Unit |

Uses sensors to monitor speed and adjust feeding for best results. |

|

Discharge Chute |

Directs finished wood chips out of the machine. |

|

Power Source |

Usually a gas engine or electric motor. Turns the disc or drum. |

|

Safety Features |

Includes shields, emergency stops, and brackets to protect users. |

The control unit in modern wood chippers stores important data. It shows the speed of the rollers and disc. If the machine runs too fast or too slow, the control unit can alert the user. Some chippers let users set the desired chip length and cutter speed. This helps make wood chips that fit different needs, like mulch or playground cover.

Performance tests show that the cutting mechanism affects both energy use and productivity. The table below compares common types:

|

Cutting Mechanism |

Energy Consumption (relative) |

Productivity (tons/hour) |

Notes on Efficiency and Application |

|---|---|---|---|

|

Two-cylinder cutting mechanism |

Baseline (most energy efficient) |

Up to 0.88 |

Lowest energy use; highest productivity; best for branches |

|

Disc cutting mechanism |

0.47 |

Moderate productivity; higher energy use |

|

|

Drum cutting mechanism |

369% - 478% higher than baseline |

0.06 |

Lowest productivity; highest energy use |

The type of wood chipper and its power level affect how much wood it can handle. Drum and disc chippers with strong engines process both branchwood and whole trees. They produce high-quality wood chips and work well for large jobs. Machines with auto-feed controls and sharp blades keep the process smooth and reduce the risk of clogs.

Note: Regular maintenance, like sharpening blades and checking sensors, keeps the wood chipper working at its best.

Wood Chipper Types

Electric vs Gas

Homeowners can pick electric or gas-powered wood chippers. Electric chippers plug into a wall outlet. They are quiet and do not make fumes. These machines need little care and work for small branches. Electric models are light and easy to move. But they are not very strong and cannot run far from power. Users must stay near an outlet.

Gas-powered chippers use a gasoline engine. They have more power and can chip bigger branches. These machines work well where there is no electricity. Gas chippers are easy to move and can be towed or drive themselves. They recover fast after hard work but need more care. Gas engines are loud and make exhaust fumes.

Tip: Electric chippers are best for small yards and light work. Gas chippers are better for big yards and tough jobs.

Drum, Disk, Screw

There are also drum, disk, and screw wood chippers. Each kind has its own features and uses.

-

Drum chippers have a big spinning drum with blades. They can chip lots of wood and thick branches. Landscapers and tree workers use drum chippers for hard jobs.

-

Disk chippers use angled discs with sharp knives. They make even chips and are good for small branches. These machines use less power and fuel than drum chippers.

-

Screw chippers have a turning screw that cuts wood. They make even chips and let users change blades for different sizes. Screw chippers are rare but good for special jobs.

The table below shows how these types compare:

|

Wood Chipper Type |

Performance Characteristics |

Suitable Application |

Power Source |

Maintenance |

Noise |

Mobility |

|---|---|---|---|---|---|---|

|

Drum Chipper |

High-volume, handles large branches |

Heavy-duty, large branches |

Gas or PTO |

Moderate to high |

High |

Less portable |

|

Disc Chipper |

Uniform chips, efficient for small branches |

Landscaping, bedding |

Gas or electric |

Moderate |

Moderate |

Portable |

|

Screw Chipper |

Slower, uniform cutting |

Specialized needs |

Varies |

Moderate |

Moderate |

Variable |

|

Gas-Powered |

High power, portable |

Large branches, remote use |

Gasoline |

Regular |

High |

Portable |

|

Electric |

Quiet, low maintenance |

Small branches, yard debris |

Electric |

Low |

Low |

Lightweight |

These differences help people choose the right chipper. Drum chippers are for big jobs. Disk chippers make neat chips for gardens. Screw chippers give special chip sizes. Electric and gas chippers let you pick the power, noise, and how easy they are to move.

How to Use a Chipper

Safety Tips

Safety comes first when learning how to use a chipper. Operators should always wear protective gear. This includes safety glasses, gloves, long pants, and sturdy shoes. Ear protection helps reduce noise damage. Before starting, users must check that the area is clear of pets and children.

Here are important safety steps:

-

Read the manual before using the chipper.

-

Inspect the machine for loose bolts or damaged parts.

-

Place the chipper on flat, stable ground.

-

Feed branches into the hopper slowly. Use a push stick for short pieces.

-

Stand to the side of the hopper, not directly in front.

-

Never reach into the hopper while the chipper runs.

-

Turn off the engine before clearing jams or making adjustments.

Tip: Keep hands and clothing away from moving parts at all times.

Maintenance Basics

Regular care keeps a chipper working well. Operators should check the blades for sharpness after each use. Dull blades make the machine work harder and can cause jams. Cleaning the hopper and discharge chute removes leftover wood chips and dust.

A simple maintenance checklist:

-

Check oil and fuel levels before each use.

-

Sharpen or replace blades as needed.

-

Tighten loose bolts and screws.

-

Clean air filters to prevent engine problems.

-

Store the chipper in a dry place to avoid rust.

A well-maintained chipper lasts longer and works better. Good care also keeps the machine safe for everyone.

A wood chipper lets people change yard waste into chips. These chips are good for gardens and paths. It is important to pick the right chipper and use it safely. Many people like electric models because they are quiet and clean. Experts say you should choose a chipper that fits your job.

Checklist for choosing and maintaining a chipper:

-

Check branch size and power needs

-

Look for safety features

-

Keep blades sharp

-

Clean after each use

-

Ask for expert advice when buying

FAQ

How often should someone sharpen wood chipper blades?

Blades need sharpening after every 10 to 20 hours of use. Dull blades slow the machine and can cause jams. Regular checks help keep the chipper safe and efficient.

Can a wood chipper handle wet or green wood?

Most wood chippers can process wet or green wood, but dry wood chips more easily. Wet material may clog the machine. Users should feed smaller amounts and clean the chipper after use.

What size branches can a typical home chipper handle?

Home wood chippers usually handle branches up to 2 or 3 inches thick. Always check the manufacturer’s guide for the maximum branch size. Feeding larger branches may damage the chipper.

Is it safe to wear loose clothing while using a chipper?

Never wear loose clothing near a wood chipper. Loose sleeves or jewelry can get caught in moving parts. Operators should wear fitted clothes and tie back long hair.

What should someone do if the chipper jams?

-

Turn off the chipper and unplug it.

-

Wait for all parts to stop moving.

-

Use a stick or tool to clear the jam.

-

Never reach inside with hands.

Safety comes first when clearing jams.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.