|

Method |

Time per Bird |

|---|---|

|

Chicken Plucker |

|

|

Manual Hand Plucking |

Several minutes |

With this kind of speed and cleaner results, you can process more birds with less effort. Picture how much easier your farm days could feel with this tool in your shed.

Key Takeaways

-

A chicken plucker helps you save lots of time. It works much faster than hand plucking. You can finish birds in seconds, not minutes. Chicken pluckers do the hard work for you. Your hands and back do not get tired or sore. The machine removes feathers better and more evenly. There are fewer missed feathers and less skin damage. Buying a chicken plucker helps you get more done. You need less help from others. Farm work becomes easier and quicker. Clean and take care of your chicken plucker often. This helps it last for many years.

Manual Plucking Challenges

Time and Labor

You know how it goes. You finish processing a chicken, but your hands already feel tired. Manual plucking takes a lot of time and energy. If you have more than a few birds, the job can stretch on for hours. You might start strong, but after the third or fourth chicken, your fingers ache and your back starts to complain.

-

Manual plucking often means:

-

Spending 20–25 minutes on each bird

-

Repeating the same motion over and over

-

Taking breaks because your hands cramp up

-

Tip: If you want to process a whole flock, you need to plan for a long day. Manual plucking can slow down your entire workflow.

You might even need help from family or friends. That can turn a simple task into a group project. Sometimes, you just want to get the job done and move on to other chores. Manual plucking makes that tough.

Mess and Inconsistency

Plucking by hand gets messy fast. Feathers fly everywhere. Wet skin and sticky down cling to your fingers. The work area fills up with loose feathers, and cleanup takes almost as long as the plucking itself.

-

Common problems you might face:

-

Feathers stick to your hands and clothes

-

Some spots get missed, leaving patches behind

-

You risk tearing the skin or damaging the meat

-

Nobody likes finding stray feathers after cooking. Hand plucking often leaves small pinfeathers behind. That means you spend extra time picking at the bird, trying to get it just right.

You want your chickens to look clean and ready for the table. Manual plucking makes that goal harder to reach. The results can vary from bird to bird, depending on how tired you feel or how much time you have. Consistency is tough when you do everything by hand.

Chicken Plucker Benefits

Speed and Efficiency

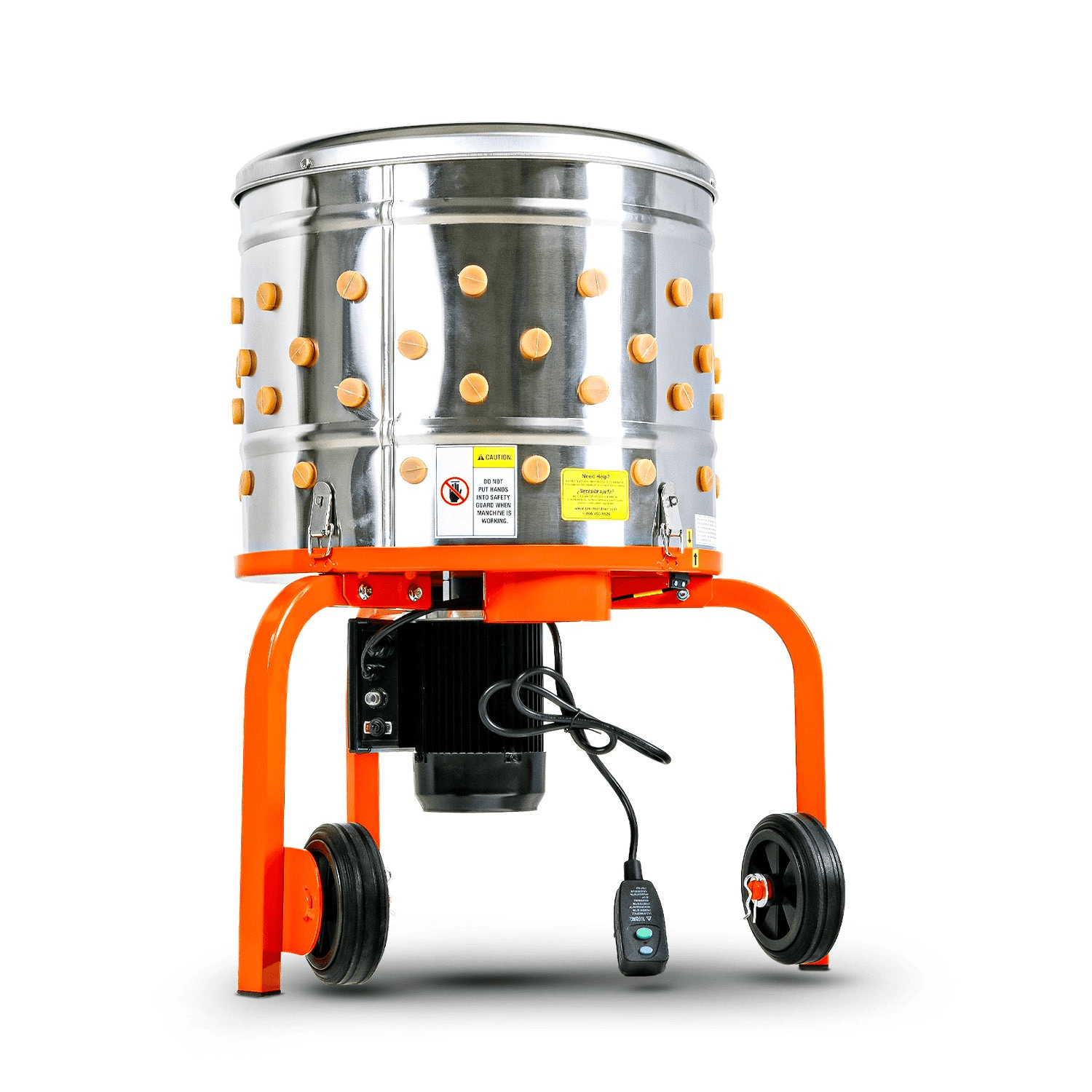

You want to get through your flock quickly. A chicken plucker makes that possible. Instead of spending 20 to 25 minutes on each bird, you can finish in just 15 to 30 seconds. That’s a huge difference! Some machines even let you process several birds at once, so you can move from one step to the next without waiting around.

-

Most chicken pluckers spin at 400 to 500 rpm.

-

They remove up to 95% of feathers in one go.

-

You can process about 4 kilograms of birds every minute.

If you have a big batch, you’ll notice how much faster your day goes. You can finish your poultry processing in a fraction of the time. That means more time for other chores or even a well-deserved break.

Tip: Batch processing with a chicken plucker keeps your workflow smooth and steady. You won’t get stuck waiting for one bird to finish before starting the next.

Cleaner Results

You want your chickens to look neat and ready for the table. A chicken plucker helps you get there. The machine uses soft rubber fingers to pull out feathers gently but firmly. This method leaves fewer pinfeathers behind and keeps the skin looking good.

-

Birds come out cleaner, with fewer missed spots.

-

The risk of tearing the skin or damaging the meat drops.

-

You spend less time picking at stubborn feathers.

When you use a chicken plucker, you get more consistent results. Each bird looks just as good as the last. You can feel proud of your finished product, whether you’re cooking for your family or selling at the market.

Less Physical Strain

Manual plucking wears you out. Your hands cramp, your back aches, and you feel tired before you even finish. With a chicken plucker, you let the machine do the hard work. You just load the birds and watch the feathers come off.

-

The rotating rubber fingers do the plucking for you.

-

You don’t have to pull, twist, or strain your hands.

-

The machine keeps the birds moving smoothly, so you don’t risk breaking bones or damaging joints.

You’ll notice you have more energy at the end of the day. Poultry processing feels less like a chore and more like a simple step in your routine. You can focus on other tasks, knowing the hardest part is already done.

Using a chicken plucker means less mess, less stress, and a much easier time getting your birds ready.

Small Farm Advantages

Productivity Boost

You want to get more done in less time. A chicken plucker helps you do just that. With manual plucking, you might process about 20 chickens per hour. When you use an automatic chicken plucker, you can handle up to 200 chickens in the same time. That’s a huge jump! Some farms even see a 30% increase in output during their first year with this tool.

|

Metric |

Manual Plucking |

Automatic Chicken Plucker |

|---|---|---|

|

Processing Capacity |

~20 chickens per hour |

Up to 200 chickens per hour |

|

Output Increase (Case) |

N/A |

30% increase in output in 1 year |

|

Labor Requirement |

High |

Reduced labor needed |

|

Time Efficiency |

Longer time per bird |

Significantly reduced plucking time |

You save time, use less energy, and get more birds ready for sale or your freezer. You can even work with a smaller crew and still finish faster.

Versatility for Flock Size

Your flock size might change from season to season. Sometimes you have just a few birds, and other times you have a big batch. Chicken pluckers work well for both. They handle different bird sizes and species, so you don’t need special equipment for every job.

-

You can process 6 birds per person per hour with basic tools.

-

With a chicken plucker, you can handle up to 15 birds per person per hour.

-

The machine works for small or large flocks, giving you flexibility.

You can scale up or down as needed. This makes your small farm more adaptable and ready for anything.

Consistent Quality

You want every chicken to look clean and ready for the table. Chicken pluckers help you get there. They remove feathers evenly and gently, so you see fewer missed spots and less skin damage. Machines like the CarcassFormer show high accuracy in finding leftover feathers and defects, which means better results every time.

Food safety also improves. After plucking, tests show a big drop in bacteria like Campylobacter and Pseudomonas. Cleaner birds mean safer meals for your family or customers.

Tip: Consistent quality helps you build trust with buyers and makes your farm stand out at the market.

Chicken Plucker Investment

Upfront Cost

Buying a chicken plucker feels like a big step. You might look at the price tag and wonder if it’s worth it. Most models for small farms cost between $300 and $800. Some heavy-duty machines go higher, but you don’t need those unless you process hundreds of birds every week.

You pay more up front than you would for hand tools. That’s true. But think about what you get for your money:

-

Time saved: You spend less time on each bird.

-

Less labor: You don’t need as many helpers.

-

Cleaner workspace: The mess stays under control.

Note: Many small scale processors find that the investment pays off after just a few batches, especially during busy seasons.

If you process chickens for your family or sell at the market, a chicken plucker can help you grow. You can handle more birds without hiring extra hands or spending all day in the shed.

Long-Term Value

Let’s talk about the long run. A chicken plucker is not just a one-season tool. With a little care, you can use it for years. Some farmers report their machines still work after processing thousands of birds.

Here’s what you get when you look at the big picture:

|

Benefit |

Manual Plucking |

Chicken Plucker |

|---|---|---|

|

Time per bird |

20-25 minutes |

20-30 seconds |

|

Labor needed |

High |

Low |

|

Consistency |

Varies |

Reliable |

|

Durability |

N/A |

Years of use |

You save money over time. You don’t need to pay for extra labor. You don’t waste hours on each batch. You also avoid buying new hand tools every year.

If you keep your chicken plucker clean and dry, it will last even longer. A little maintenance goes a long way.

You also get peace of mind. You know you can process your flock quickly, even if your numbers grow. That means you can take on new customers or expand your farm without worrying about bottlenecks.

A chicken plucker is more than a gadget. It’s a partner that helps you work smarter, not harder.

Choosing a Chicken Plucker

Size and Capacity

Picking the right chicken plucker starts with knowing your needs. You want a machine that matches your flock size and fits your space. If you raise a few chickens at a time, a small tabletop plucker might work best. If you process larger batches, you’ll need a bigger drum-style plucker.

Here’s a quick guide to help you decide:

|

Flock Size |

Plucker Type |

Birds per Batch |

|---|---|---|

|

1–5 birds |

Tabletop/Handheld |

1 |

|

6–20 birds |

Small Drum |

1–2 |

|

20+ birds |

Large Drum |

3–5+ |

-

Small pluckers are easy to store and move. You can use them for backyard flocks or small family farms.

-

Large pluckers handle more birds at once. These save you time if you process big batches.

Tip: Think about your future plans. If you want to grow your flock, choose a plucker with a little extra capacity.

You also want to check the power source. Some pluckers run on standard outlets. Others need more power. Make sure your setup matches the machine.

Maintenance Tips

A chicken plucker works best when you take care of it. Regular cleaning and simple checks keep it running for years.

Here’s how you can keep your plucker in top shape:

-

Clean after each use. Rinse off feathers and dirt. Wipe down the drum and rubber fingers.

-

Check the rubber fingers. Look for cracks or wear. Replace any that look damaged.

-

Tighten bolts and screws. Vibrations can loosen parts over time.

-

Lubricate moving parts. Use food-safe oil on bearings and gears.

-

Store in a dry place. Moisture can cause rust or mold.

If you spot a problem, fix it right away. Small repairs now can save you from big headaches later.

A well-maintained chicken plucker will serve you season after season. You’ll spend less time fixing and more time processing your flock.

A chicken plucker can change your farm life. You save hours each week, avoid sore hands, and get cleaner birds every time. Just look at the numbers:

|

Method |

Feathers Removed |

Time per Bird |

|---|---|---|

|

Manual Plucker |

4 min |

|

|

Wet Plucker |

>95% |

2–3 min |

-

Local processing gives you fresher, tastier chicken.

-

Even with higher costs, many people love the quality and trust local farms.

Why not make your next processing day easier and more productive? Your future self will thank you!

FAQ

How do you clean a chicken plucker after use?

You should rinse off feathers and dirt right away. Wipe down the drum and rubber fingers. Dry everything before storing.

Tip: Clean your plucker after every use to keep it working well.

Can a chicken plucker handle other birds?

Yes! You can use most chicken pluckers for ducks, turkeys, and even quail.

-

Check your machine’s manual for size limits.

-

Adjust the time for different birds.

Is a chicken plucker safe to use?

Chicken pluckers are safe if you follow the instructions.

-

Keep hands away from moving parts.

-

Unplug the machine before cleaning or fixing it.

How long does a chicken plucker last?

With good care, your chicken plucker can last for years.

Many farmers process thousands of birds before needing repairs.

Keep it clean and dry for the best results.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.