If you’re doing small projects or DIY tasks, a jumping jack compactor can really help. This strong tool, also called a jumping jack tamper, packs down materials like dirt, gravel, and asphalt fast. It’s great for making solid surfaces, like when you’re building a base, flattening dirt for grass, or packing gravel for driveways.

Why use a jumping jack tamper?

It works fast and gives great results.

You can make smooth, sturdy surfaces for patios or paths.

It’s useful for yard work, building, and fixing roads.

Because it’s easy to use and very flexible, a jumping jack tamper is perfect for beginners who want to finish projects like experts.

Key Takeaways

A jumping jack compactor is great for small home projects. It helps make surfaces firm fast and easily.

Pick the right tool based on the material and area size. This ensures better results.

Always wear safety gear like gloves and goggles to stay safe.

How a Jumping Jack Compactor Works

Key parts and what they do

To know how a jumping jack tamper works, you need to learn its main parts. Each part has an important job to make the machine work well. Here's a simple list:

Part |

Job |

|---|---|

Engine |

Gives power to run the machine. |

Bellows |

Moves energy and softens shocks. |

Ramming Shoe |

Pushes force onto the ground. |

Handle Assembly |

Helps control and reduces shaking. |

Fuel Tank |

Holds gas or fuel mix. |

Air Filter |

Keeps dirt out of the engine. |

The engine is like the brain of the compactor. It creates the energy needed to make it work. The bellows pass this energy to the ramming shoe and also reduce shaking. The ramming shoe hits the ground to pack it down. The handle assembly lets you steer the machine and feel less vibration. The fuel tank keeps the engine running by holding fuel, while the air filter stops dirt from getting inside.

When all these parts work together, the jumping jack tamper becomes a strong tool for packing soil, gravel, or asphalt.

How the compaction process works

The jumping jack tamper is great at packing materials tightly. But how does it do this? Let’s explain.

It uses both force and vibration to pack the ground. The engine powers the ramming shoe, which hits the ground again and again. This force pushes soil particles closer, removing air and water. The result is a firm and stable surface.

Experts say the energy needed to pack soil can range from 595 KJ/m³ to 2072 KJ/m³. This depends on the type of soil and how packed it needs to be. The ramming shoe’s quick movements deliver this energy. These movements also cut through the soil, making it even denser and strong enough to hold heavy things.

The process is very reliable. Studies show that the compactor’s mechanics are 90.8% accurate in achieving the right results. Its vibrations also spread evenly, ensuring the ground is packed the same everywhere.

By using force, vibration, and accuracy, the jumping jack compactor turns loose soil into a solid base. Whether you’re working on a driveway, patio, or building site, this tool makes the job easy and fast.

Choosing the Right Jumping Jack Compactor

Things to think about for your project

Choosing the right jumping jack tamper is very important. Think about what material you’ll be compacting. Is it soil, gravel, or asphalt? Some tampers work better with certain materials. Also, check the size of your work area. Small tampers are good for tight spots. Bigger ones cover more ground faster.

The machine’s weight is another thing to consider. Heavier tampers pack harder but are harder to move. If you’re a beginner, a lighter tamper might be easier to use. Look at the engine power too. Stronger engines work faster but use more fuel. Lastly, think about your budget. There are many options, so you can find one that works for you.

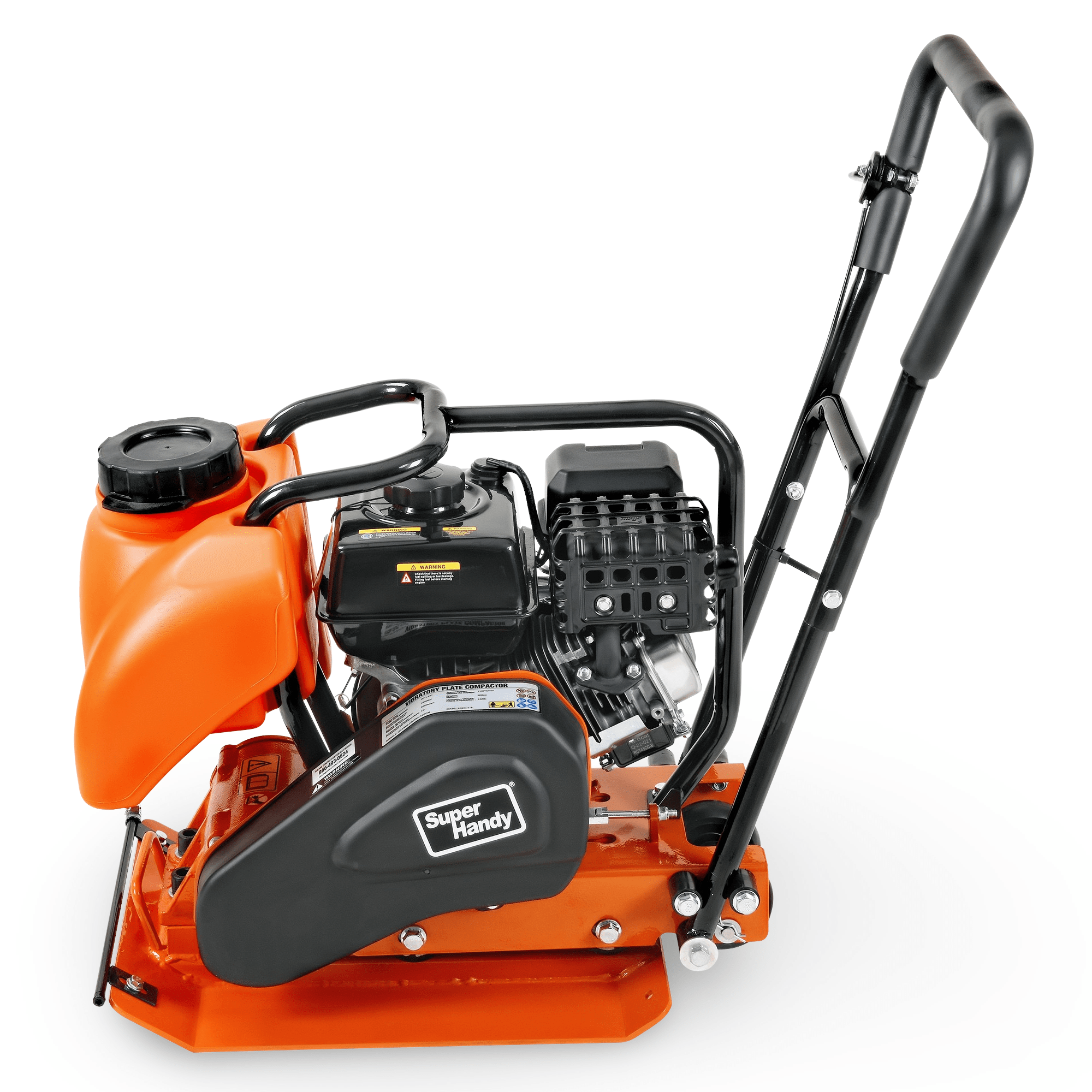

Why Superhandy tampers are a great choice

Superhandy jumping jack tampers are great for both beginners and experts. They are made to last and handle tough jobs. Their engines are strong but don’t waste fuel. Superhandy tampers also reduce vibration, making them easier to control.

These tampers are lightweight, so they’re easy to move around. They have simple controls, so they’re not hard to use. Whether you’re doing a small project or a big one, Superhandy tampers work well every time.

If you want a tamper that’s easy to use, affordable, and high-quality, Superhandy is a great pick. They’re known for being reliable and worth the money.

Step-by-Step Guide to Using a Jumping Jack Tamper

Getting the site ready for compaction

Before using a jumping jack tamper, you must prepare the area. A well-prepared site gives better results and keeps you safer. Follow these steps to get started:

Clear the area: Take away trash, rocks, or big objects that could block the tamper.

Level the surface: Use a rake or shovel to make the ground flat. This helps the tamper work better.

Identify soil type: Different soils need different methods. Sandy soil is easier to compact, but clay takes more effort.

Wear PPE: Always wear gloves, goggles, and steel-toed boots to stay safe.

A study by Yangfine Machinery shows that picking the right tamper for your soil and project size is important. Following good practices, like compacting in layers and working at a steady pace, boosts safety and efficiency. OSHA reports fewer worker injuries now because of these steps.

Using the tamper the right way

Once the site is ready, you can start using the tamper. It’s not as hard as it seems! Follow these steps to use it properly:

Start the engine: Check the fuel and air filter first. Then, start the engine as the manual says.

Position the tamper: Place the ramming shoe on the ground where you want to begin.

Hold the handle firmly: Use both hands to grip the handle. This helps you control the tamper and feel less vibration.

Move steadily: Guide the tamper in a straight line at a steady speed. Don’t rush, or the compaction might be uneven.

Overlap passes: Slightly overlap each pass to make sure you don’t miss any spots.

Experts say keeping a steady pace and overlapping passes makes the job more efficient and even. By following these steps, you’ll get great results while staying safe.

Tips for even compaction

Even compaction is important for a strong and lasting surface. Uneven areas can cause problems later. Use these tips to get consistent results:

Compact in layers: Don’t try to compact all at once. Work in 4-6 inch layers.

Use straight passes: Move the tamper in straight lines, overlapping each pass a little. This ensures full coverage.

Check compaction depth: Measure often to make sure you’re reaching the right depth.

Adjust for material type: Soil and asphalt need different methods. For example, asphalt may need extra passes to get dense enough.

Experts suggest a step-by-step approach with overlapping passes for the best results. Studies show that getting even compaction can be tricky because of soil differences. But by following these tips, you can create a solid base for your project.

Maintenance Tips for Your Jumping Jack Compactor

Taking care of your jumping jack compactor is simple. With regular care, it will last longer and work well. Follow these easy maintenance tips to keep it in great shape.

Regular checks and care

Checking your compactor often keeps it working smoothly. Before using it, look at the engine oil, hydraulic fluid, and coolant levels. Add more if needed to avoid damage. Each week, check the retaining pin and tool to make sure they’re tight and not broken. Once a month, inspect the tool shank and bushings for any wear or cracks. These small checks can stop bigger problems later.

Here’s a handy table for when to do maintenance:

Time Frame |

Task to Complete |

|---|---|

Daily |

Check oil, hydraulic fluid, and coolant. Add more if needed. |

Weekly |

Look at the retaining pin and tool every 10 hours. |

Monthly |

Check the tool shank and bushings every 50 hours. |

Every 50 hours |

Inspect the hydraulic hoses. |

Annually |

Service the hammers or after 600 hours of use. |

Following this schedule helps your compactor stay in good condition and avoids expensive fixes.

Cleaning and storing tips

Clean your compactor after each use. Dirt and leftover materials can stick to it and cause problems. Use a brush or cloth to wipe it down, especially the ramming shoe and bellows.

When storing it, pick a dry and safe place. Wet or bad weather can cause rust and other damage. A clean and stored compactor will be ready for your next project.

When to get expert help

Sometimes, your compactor might need a professional. If it makes strange sounds, works poorly, or won’t start, call a technician. Also, get the hammers serviced once a year. This keeps your machine running well for a long time.

Daily checks can catch small problems early. But if you’re unsure, ask for help. Fixing issues quickly is always better than waiting.

Safety Guidelines for Using a Jumping Jack Compactor

Important Safety Gear (PPE)

Before starting, wear the right safety gear. PPE is not optional—it’s necessary. Wear a hard hat to protect your head from falling objects. Use earmuffs or earplugs to block loud engine noise. Gloves help you grip better and stop blisters. Steel-toed boots protect your feet from heavy items.

Don’t skip eye protection. Goggles or safety glasses keep dust out of your eyes. If it’s dusty, wear a mask to protect your lungs. Wearing this gear is the first step to staying safe.

Safe Use and Handling Tips

Using a jumping jack compactor safely takes more than turning it on. Follow these tips to avoid accidents:

Safety Rule |

What It Means |

|---|---|

Use the Right Tool |

Pick the correct compactor for your soil and project. |

Check Safety Features |

Look for stop switches and isolator rubbers for extra safety. |

Be Qualified |

Operators should be 18+ and know how to use the machine. |

Wear Protective Gear |

Always wear a hard hat, gloves, ear protection, and steel-toed boots. |

Work in Open Areas |

Use the machine in places with good airflow to avoid exhaust fumes. |

Be Careful on Slopes |

Take extra care on uneven or sloped ground to prevent tipping. |

Read Instructions |

Learn the safety and operation steps before starting the machine. |

These steps keep you safe and help the compactor work better.

Avoiding Dangers While Working

Jumping jack compactors are strong but can be risky if misused. Losing control is a common danger. Hold the handle tightly and stand steady. Don’t use the machine on steep or unstable ground—it might tip over.

Exhaust fumes are another risk. Always work in open spaces with fresh air. If the machine makes odd noises or shakes too much, stop and check it. Ignoring these signs can cause damage or injuries.

Lastly, don’t rush. Overlap your passes and move at a steady speed. This ensures even compaction and lowers accident risks. Stay focused and follow these tips to avoid most problems.

Troubleshooting Common Issues with Jumping Jack Tampers

Spotting performance problems

If your jumping jack tamper isn’t working well, don’t worry. Start by noticing how it behaves. Is it not packing the ground properly? Does it shake too much or seem slow? These clues can help you find the problem.

Here’s a simple checklist to figure out the issue:

Uneven compaction: Look at the ramming shoe for damage or wear.

Too much vibration: Check the bellows and handle for cracks or loose parts.

Weak power: Inspect the air filter and fuel tank. Dirt or low fuel might be the cause.

Pro Tip: Write down any strange sounds or patterns in a notebook. This can help if you need to explain the issue to a professional.

Fixing engine problems

Engine issues are common but usually easy to solve. If the tamper won’t start, check the fuel. Is the tank empty or filled with old gas? Replace it with fresh fuel if needed.

If the engine sputters or stops, clean the air filter. A dirty filter can block airflow. Also, check the spark plug. If it’s worn out or dirty, replace it.

Note: Always use the manufacturer’s manual when fixing the engine. It’s the best guide for safe and proper repairs.

Knowing when to replace parts or call an expert

Sometimes, simple fixes aren’t enough. If the tamper still doesn’t work well, it may need new parts. Replace worn bellows, damaged ramming shoes, or broken engine parts quickly.

If you’re unsure about repairs, call a technician. Problems like loud noises or too much shaking often need expert help.

Regular maintenance can stop most issues. But if you’re unsure, it’s safer to get help than risk more damage.

Using a jumping jack compactor is easier than it seems. Follow this guide, and you’ll get great results quickly.

Pro Tip: Superhandy compactors are tough, easy to use, and reliable. They’re a great choice for any task.

Now it’s your chance—go ahead and start compacting!

FAQ

How is a jumping jack compactor different from a plate compactor?

Jumping jack compactors are great for sticky soils like clay. Plate compactors work better on loose materials like sand or gravel. Pick the right one for your soil type.

How often do I need to maintain my jumping jack tamper?

Check oil and fuel every day before use. Get it professionally serviced once a year or after 600 hours of use to keep it in good shape.

Pro Tip: Regular care saves money and helps your machine last longer.

Can beginners safely use a jumping jack compactor?

Yes, they can! Start with a lighter model, follow safety rules, and wear the right gear. Practice on a small spot to get comfortable.

🛠️ Tip: Always read the manual carefully before using the machine.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.