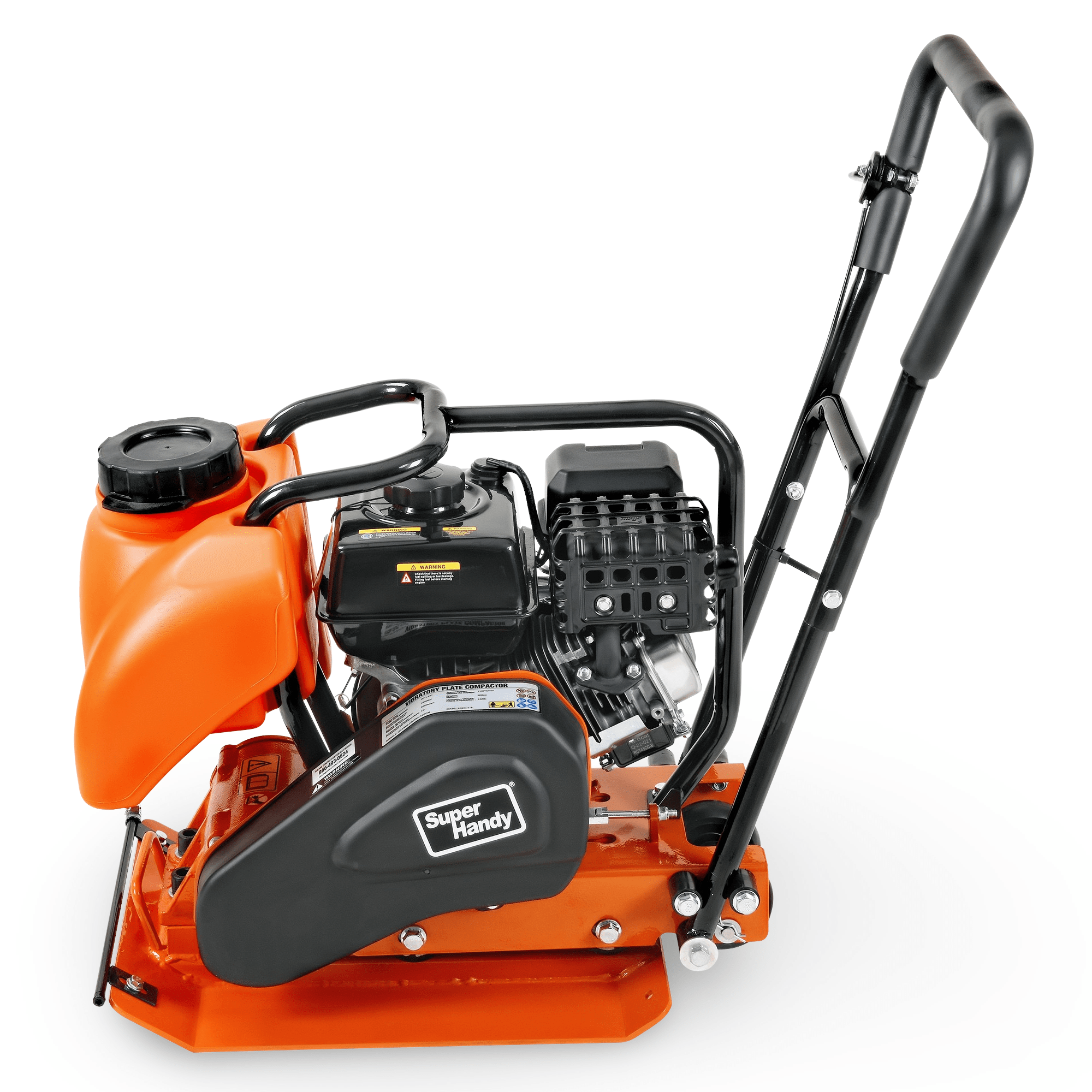

Taking care of your plate compactor helps it work well longer. Regular upkeep stops expensive fixes and keeps it working its best. You wouldn’t drive a car without changing the oil, right? Treat this machine the same way. Small care makes it dependable for every task.

Key Takeaways

Check every day for damage or loose parts to avoid problems. Use a list to keep track.

Clean the air filter and outside of the machine often. This helps it work better and last longer.

Look at belts, spark plugs, and bolts each week. This keeps it running well and saves money on repairs.

Daily Maintenance for Your Plate Compactor

Taking care of your plate compactor daily keeps it working well. Small daily efforts can stop bigger issues later. Here are the key steps for daily upkeep.

Check for damage or loose parts before using.

Before starting your hydraulic plate compactor, inspect it carefully. Look for cracks or damage on the plate, engine, or frame. Tighten any loose bolts or nuts you find. Also, check for fuel leaks. These quick checks help avoid sudden breakdowns.

Pro Tip: Use a checklist, like an Earth Compactor Operation Guide, to stay organized. A little planning keeps your machine in great shape.

Clean the air filter and wipe off dirt.

Cleaning is an important part of daily care. Dust can block the air filter, lowering the machine’s performance. Take out the air filter and clean it gently. Wipe the outside of the machine to remove dirt and grime.

Why it matters: A clean machine works better and lasts longer. Dirt can cause overheating or damage over time.

Check oil, fuel, and hydraulic fluid levels.

Your hydraulic plate compactor needs the right fluid levels to run smoothly. Look at the engine oil to see if it’s low or dirty. Inspect the fuel system for leaks or clogs. Make sure the hydraulic fluid is at the correct level. These checks are quick but very important.

-

What to check:

Dark or thick engine oil may need replacing.

Fuel filters should be clean and clear of debris.

Hydraulic fluid should be at the proper level.

Remove dirt and debris from the plate.

The plate often collects dirt, gravel, and other debris. This buildup can harm the machine or make it less effective. Use a brush or cloth to clean the plate after each use. Regular cleaning keeps the plate in good condition.

Did you know? Vibrations can cause debris to pile up fast. Cleaning daily reduces wear and helps the machine last longer.

By following these steps, your plate compactor will stay in great shape. A little daily care can save you from costly repairs and keep it running smoothly.

Weekly Maintenance Tasks

Weekly care helps your plate compactor work well and last longer. These simple tasks don’t take much time but make a big difference.

Look at the belt for damage, alignment, and tightness

The belt is very important for your machine. Check it weekly for cracks, wear, or fraying edges. Make sure it’s straight and tight enough. A loose or crooked belt can hurt performance or damage the machine.

Tip: If the belt slips or makes strange sounds, fix or replace it.

Check the spark plug and clutch for good working condition

A bad spark plug can make starting hard or lower engine power. Take out the spark plug and check for dirt or damage. Clean it or replace it if needed. Also, check the clutch. It should move smoothly when engaging or disengaging. If it feels stuck, add grease or replace it.

Tighten screws and bolts that have loosened

Using the machine often can loosen screws and bolts. Look over the machine and tighten any loose parts. This easy step keeps the machine strong and safe to use.

Add grease to moving parts for smooth operation

Greasing parts helps your machine stay in great shape. Add grease to the eccentric shaft every 200-300 hours or as your manual says. Grease lowers friction and helps parts last longer.

-

What to do:

Use grease recommended by the manufacturer.

Follow the schedule in your manual.

Doing these weekly tasks will keep your hydraulic plate compactor running better and save you money on repairs.

Long-Term Maintenance and Care

Taking care of your plate compactor for years helps it last longer. Follow these steps to keep it working well and avoid expensive fixes.

Change engine oil and replace old fuel.

Old oil and fuel can damage the engine. Dirty oil stops lubricating parts properly. Check and change oil as the manufacturer’s guidelines suggest. Fresh oil helps parts move smoothly and prevents damage.

Fuel goes bad if unused for too long. Stale fuel can block the system and lower performance. Drain old fuel and refill with fresh gasoline to keep your hydraulic plate compactor in top working condition.

Tip: Use the oil and fuel recommended in the manufacturer’s guidelines for better results.

Inspect and replace the air filter if clogged or damaged.

The air filter stops dust from entering the engine. A dirty or broken filter blocks airflow and lowers engine power. Check the air filter often during maintenance. Replace it if it looks dirty or worn.

Why it matters: A clean air filter helps the engine work better and last longer.

Examine the vibration plate for cracks or excessive wear.

The vibration plate handles heavy work, so it must stay strong. Cracks or wear can happen after lots of use. Look at the plate often for damage. Replace it if you see cracks or uneven wear to keep it working well.

Did you know? A damaged plate can lower compaction power and cause safety risks.

Replace worn-out belts and other components as needed.

Belts and moving parts wear out over time. Check for cracks, fraying, or loose belts. Replace worn parts before they break to avoid problems and keep your hydraulic plate compactor running smoothly.

-

What to look for:

Belts that are cracked, loose, or misaligned.

Parts that show wear or don’t work well.

Follow the manufacturer’s guidelines to replace parts and keep your machine in top working condition. Fixing parts early saves money and helps your plate compactor last longer.

By following these long-term care tips, your hydraulic plate compactor will stay in great shape for years. A little effort now avoids big problems later.

Troubleshooting Common Plate Compactor Issues

Even with good care, your plate compactor might have problems. Don’t panic—most issues are simple to fix. Let’s look at common problems and how to solve them.

Engine won’t start: Check fuel, spark plug, and air filter.

If the engine won’t start, it’s often an easy fix. Check these things first:

Fuel system: Make sure the fuel valve is open. If the gas is old, empty it and add fresh fuel.

Air filter: A dirty air filter can block airflow. Take it out, clean it, or replace it if needed.

Spark plug: Remove the spark plug and check it. Clean or replace it if it’s dirty or worn.

Here’s a quick guide to help you:

Problem |

Solution |

|---|---|

Dirty fuel system |

Clean the fuel system |

Clogged air filter |

Clean or replace the air filter |

Worn spark plug |

Replace the spark plug |

Carburetor needs adjustment |

Adjust the carburetor |

Pro Tip: Follow the starting steps in your manual. Simple things like closing the choke or turning the engine switch to "ON" can make a big difference.

Excessive vibration: Inspect the plate and bolts.

If your machine vibrates too much, something might be loose or broken. Check the vibration plate for cracks or damage. Tighten any loose bolts or screws. Also, make sure the machine is on a flat surface before using it.

Note: Too much vibration can harm the machine over time. Fix this issue quickly to avoid expensive repairs.

Reduced compaction performance: Check the plate and engine.

If the compactor isn’t working well, the problem might be the plate or engine. Look for dirt or cracks on the plate. Clean it or replace it if it’s damaged. Low engine power can also cause problems. Check that the engine is running well and that oil and fuel levels are correct.

“Strong engine power is key for good compaction, especially on tough jobs.”

By fixing these problems, your plate compactor will work better and last longer.

Proper Storage Tips for Your Plate Compactor

Storing your plate compactor the right way keeps it in good shape. Follow these easy steps to protect it and avoid damage.

Empty fuel and water before storing for a long time.

Before storing your plate compactor for months, drain the fuel tank. Old fuel can block the system and harm the engine. If your machine uses water, empty the water tank too. This stops freezing or mold from forming.

Tip: After draining fuel, run the engine briefly. This clears leftover gas from the carburetor and keeps it clean.

Keep it in a dry place to stop rust.

Moisture can ruin metal parts. Store your plate compactor in a dry, covered spot like a shed or garage. Avoid placing it on damp floors to prevent rust. If stored outside, use a raised platform to keep it off the ground.

Why it matters: Rust can weaken your machine and cause expensive repairs. A dry space keeps it in great condition.

Cover the machine to block dust and moisture.

A cover is a simple way to protect your plate compactor. It keeps dust, dirt, and moisture away. Make sure the cover fits well for full protection.

Safety Reminder: Always follow safety rules when storing or handling your machine. This keeps you safe and helps the machine last longer.

By using these storage tips, your plate compactor will last longer and stay ready for your next job.

Taking care of your plate compactor often is smart. It saves money and avoids big problems. Maintenance helps you find issues early. Fixing them early stops costly repairs.

Here’s why it’s important:

Benefit Type |

Explanation |

|---|---|

Regular Maintenance Advantages |

Prevents breakdowns, improves performance, and uses less fuel. |

Spotting Problems Early |

Finds issues sooner, allowing quick fixes and fewer surprises. |

Follow the routine to keep your machine working well. Small efforts now mean fewer problems later.

FAQ

1. How often should engine oil be changed in a plate compactor?

Change the engine oil every 25-50 hours of use. Follow the manufacturer’s manual for exact timing. Fresh oil helps the engine work better and last longer.

2. What to do if your plate compactor vibrates too much?

Look for loose bolts or cracks on the vibration plate. Tighten any loose parts you find. Check if the ground is uneven and fix the issue.

Tip: Use the compactor only on flat surfaces to avoid damage.

3. Can a plate compactor be used on wet soil?

Yes, but wet soil might stick to the plate. Clean the plate after using it to stop buildup. Slightly damp soil works best for compacting.

Note: Don’t use the compactor on very wet areas. It can lower how well it works.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.