You use an engine wood chipper to turn branches into small chips. The engine wood chipper has important parts. These are the engine, infeed chute, feed rollers, chipping mechanism, and discharge chute. These parts help you work fast and stay safe. Safety is very important. People can get hurt when using an engine wood chipper. Most injuries happen to fingers and hands.

Injury Type |

Percentage (%) |

Description |

|---|---|---|

Fingers and Hands |

59.3 |

Bad injuries like broken bones or lost fingers. This happens most when feeding brush. |

Lower Leg |

11.1 |

Legs can get crushed or broken by rollers or brush. |

Eye |

7.4 |

Eyes can get hurt by branches or twigs. Sometimes, the injury is very serious. |

You should check your engine wood chipper often to keep it working well. Many models can be pulled behind a car or truck. This makes them easy to move.

Engine Wood Chipper Components

A wood chipper has many important parts. These parts help turn branches into wood chips. You should know how each part works. This helps you use a professional wood chipper safely and well.

Engine and Power Source

The engine gives power to the wood chipper. There are three types of engines. These are electric, combustion, and PTO engines. Each type is good for different jobs. Electric engines work best for soft branches and small tasks. Combustion engines can handle bigger branches and tough wood. PTO engines connect to tractors for large areas.

Engine Type |

Power Output Range |

Suitable Use Case |

|---|---|---|

Electric |

1,800 W (2.41 HP) to 3,000 W (4 HP) |

Moderate use, suitable for soft branches up to 50 mm in diameter |

Combustion |

6 HP to 200 HP |

Intensive use, suitable for all types of wood up to 75 mm in diameter |

PTO (Power Take-Off) |

Varies with tractor |

Used for larger areas, more affordable and easier to use in certain terrains |

A stronger engine lets you chip bigger branches. You can also clear more debris. This means you work faster and get fewer clogs. The engine controls how fast the blades spin. Faster blades make wood chips quicker.

More horsepower lets you chip bigger branches.

Strong engines help stop clogs and delays.

Fast blade speed makes chipping more efficient.

Infeed Chute and Hopper

You put branches into the chipper using the infeed chute and hopper. The chute design keeps you safe and helps you work quickly. A good chute controls how branches go in. This lowers the chance of jams and spills. The angle and surface help branches move smoothly.

Safe loading keeps your hands safe.

The chute’s angle helps feed branches better.

Feed System and Rollers

The feed system pulls branches into the chipper. There are two main types. These are hydraulic infeed and gravity assist infeed.

Hydraulic infeed uses rollers powered by hydraulics. You can change the speed and direction for different branches.

Gravity assist infeed uses a steep chute and strong flywheel. Gravity helps move branches into the chipper.

Feed rollers keep branches moving and stop jams. If debris builds up, jams can happen. Clean and check the rollers often. This keeps your professional wood chipper working well.

Regular cleaning helps prevent jams.

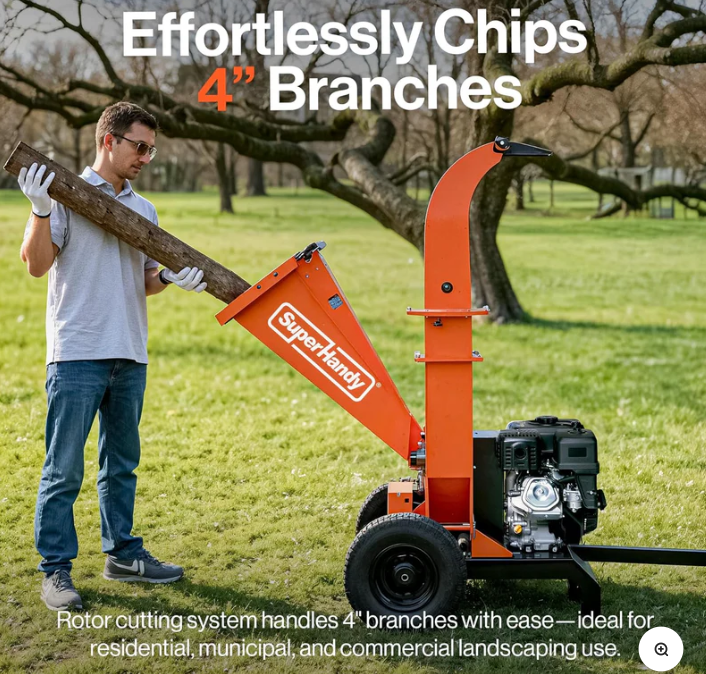

Chipping Mechanism

The chipping mechanism is the main part of the chipper. It uses sharp blades on a flywheel or spinning disc. When branches go in, the blades cut them into small pieces. Some models have twin flywheels. These help push wood chips out faster and farther.

Flywheel blades chip material quickly.

Twin flywheels push chips out with more force.

Disc chippers use a spinning disc with blades to cut wood.

The engine sends power to the chipping mechanism. It uses v-belts and pulleys.

Component |

Function |

|---|---|

V-belt |

|

Conical pulleys |

Open against springs to help the v-belt move power to the blades. |

Discharge Chute

The discharge chute sends wood chips out of the chipper. Good design keeps chips flowing and stops clogs. The chute resists damage and controls chip speed. It also helps keep dust and spills low. This makes your work area safer.

Design Feature |

|

|---|---|

Material flow characteristics |

Ensures smooth transfer and minimizes blockages. |

Impact and wear resistance |

Reduces wear and tear, maintaining efficiency over time. |

Velocity control |

Regulates material speed to prevent buildup and spillage. |

Dust and spillage prevention |

Minimizes hazards and maintains a clean working environment. |

Modern wood chippers let you control where chips go. You can change the feed roller speed with hydraulic controls. Some advanced models use electronic systems. These change feed speed based on engine power. This helps you pick chip size and where chips land.

Safety Features

Safety features protect you when you use a wood chipper. Smart control panels show oil levels, water temperature, and runtime. Emergency stop buttons let you stop the chipper fast if needed. Intelligent feeding systems stop or reverse if there is a jam or something strange. You also get manual controls for emergencies.

Safety Feature |

Description |

|---|---|

Smart Control Panels |

Displays vital stats like oil levels, water temperature, and runtime for early issue identification. |

Emergency Stop Mechanisms |

Allows for immediate cessation of operation in case of danger. |

Intelligent Feeding Systems |

Automatically stops or reverses if a jam or foreign object is detected, protecting the machine. |

Independent Conveyor System |

Enables manual control of feeding during emergencies, enhancing operator safety. |

Other safety features include bump bars that stop the feed wheel. There are forward-reverse bars for better control. Longer infeed designs lower accident risk. You also find operator toolbars, last chance tables, and rope shear devices for extra safety.

Emergency stop switches are on the sides and top of the funnel. If you press one, the rollers stop right away. You must turn the red knob and reset the control bar to start again. This stops accidental restarts and lets others help if needed.

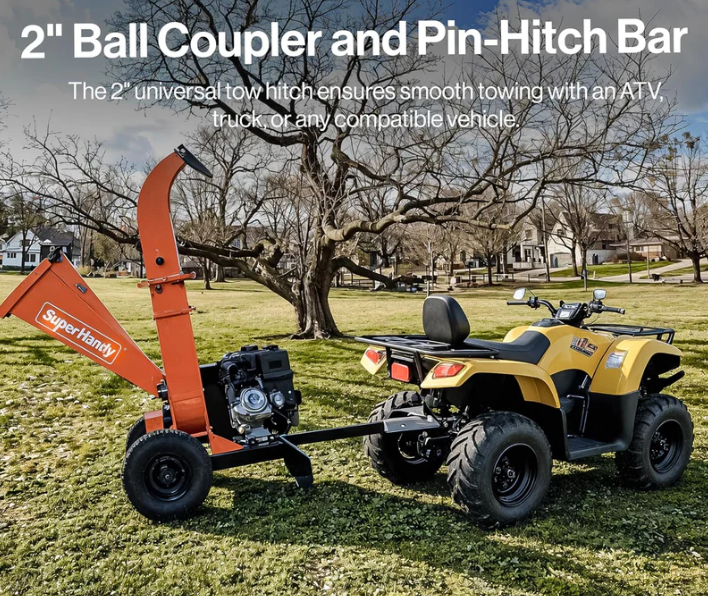

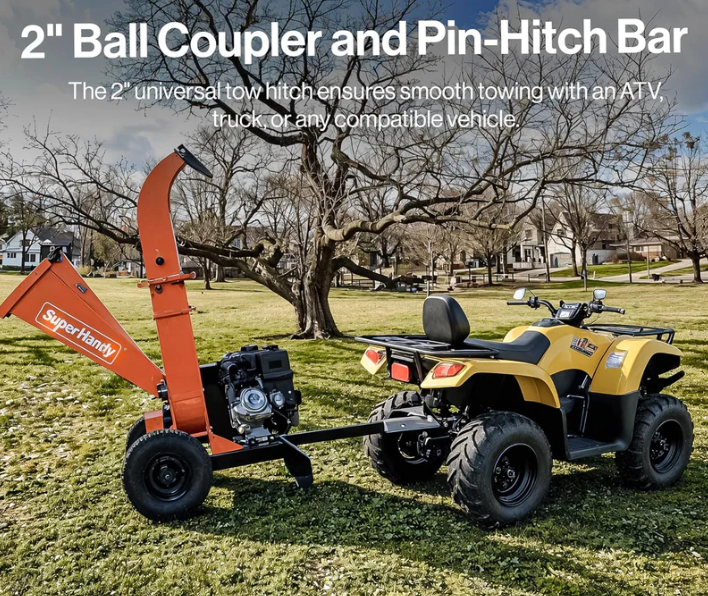

Tow-Behind Feature

Tow-behind wood chippers are easy to move. You can take them to different places. This helps when you work on big properties or landscaping jobs. These models have strong engines. They can handle branches and small trees easily. You save time and effort. Tow-behind wood chippers let you make mulch, clear land, and work with many types of wood and debris.

Mobility lets you move the chipper easily.

Efficiency helps you finish jobs faster.

Versatility means you can chip different materials.

You need to know the weight and towing rules for tow-behind models.

Requirement |

Details |

|---|---|

3500kg |

|

Maximum wood chipper weight (without B+E) |

750kg |

Combined gross weight limit (with B+E) |

7000kg |

Typical weight of Timberwolf Sub 750kg wood chippers |

Under 750kg (even when full of fuel) |

A professional wood chipper with tow-behind features makes work easier and safer. You can move it where you need and handle big jobs with less effort.

Tip: Always check your vehicle’s towing limits before moving a tow-behind wood chipper. This keeps you safe and protects your equipment.

Wood Chipper Operation

Wood Chipping Process

You use a wood chipper to turn branches and brush into small chips. The wood chipping process starts when you feed material into the infeed chute. The feed system pulls the wood inside. The chipping mechanism cuts the wood into chips. The discharge chute sends the chips out. Each part works together to make the job safe and fast.

Tip: Always wear safety glasses and gloves before you start the wood chipping process. This keeps you safe from flying debris.

Step-by-Step Sequence

You can follow these steps to use a wood chipper safely and efficiently:

Feed the infeed chute: Place branches or brush into the chute. Make sure the material fits the chipper’s size limit.

Material is pulled in: The feed rollers grab the wood and pull it toward the chipping mechanism.

Chipping process: The blades inside the mechanism cut the wood into small chips. The type of mechanism (drum, disc, or flywheel) affects how the wood is chipped.

Discharge of wood chips: The chips exit through the discharge chute. You can adjust the chute to control where the chips land.

A good sequence of operation helps you get clean chips and use less energy. When you use the right technique, you also lower the risk of accidents. The quality of the chips depends on the sharpness and angle of the blades. If you use the wood chipper correctly, you help the blades last longer and keep the machine safe.

Note: Stay a safe distance from the hopper during operation. Make sure you have proper training before using a wood chipper.

Types of Chipping Mechanisms

Wood chippers use different processing mechanisms to cut wood. The main types are drum, disc, and twin flywheel. Each mechanism has its own strengths and weaknesses.

Chipping Mechanism |

Description |

Performance Characteristics |

|---|---|---|

Drum Chippers |

A rotating drum with blades tumbles and chips the material. |

Fast operation, but loud and can jam if not used carefully. |

Disc Chippers |

A steel disc with blades spins at high speed to cut wood. |

Many sizes and horsepower options. Performance depends on the model. |

Twin Flywheel |

One flywheel chips the wood, the other helps push chips out. |

Very efficient for leafy or green material. |

Drum chippers work quickly but make a lot of noise. You need to watch for jams.

Disc chippers give you more choices in size and power. Many commercial wood chippers use this mechanism because it handles many types of wood.

Twin flywheel chippers work well for light, leafy branches. The second flywheel helps move chips out fast.

The first wood chipper design used a steel disc with blades. This design is still common today, especially in commercial models.

Self-Feeding vs. Manual Feeding

You can choose between self-feeding and manual feeding wood chippers. Each type has benefits and drawbacks.

Feature |

Gravity Feed Wood Chippers |

Hydraulic Feed Wood Chippers |

|---|---|---|

Pros |

Simple and affordable |

Easy, effortless feeding |

Low maintenance |

Better control over feed rate |

|

Portable |

Handles tough, large material |

|

Good for small, straight branches |

Safer and more productive |

|

Cons |

Needs more manual effort |

Higher cost |

Can jam more easily |

More complex maintenance |

|

Feed rate is not steady |

Heavier to move |

|

Not good for large jobs |

Self-feeding chippers (gravity feed) use the angle of the chute and the spinning mechanism to pull in wood. You need to push the material in and watch for jams.

Hydraulic feed chippers use powered rollers. You can control the feed rate and even reverse the feed if needed. This makes the operation safer and more efficient, especially for big branches.

Self-feeding chippers work best for small, straight branches. Manual feeding takes more effort and can be slower. Hydraulic feed chippers handle larger jobs and give you more control. You can adjust the feed rate to match the size and type of wood.

If you want to chip a lot of material or work with tough branches, a hydraulic feed wood chipper is a better choice. For small jobs, a gravity feed chipper is simple and easy to use.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.