Using an electric winch safely keeps you and your gear safe. Taking care of it often helps stop accidents. It also helps your marine electric winch work well. If you stick to a regular maintenance plan, you get these good things:

Fewer times the winch breaks and less chance of getting hurt

The winch lasts longer

Every operator gets better results

Electric Winch Inspection

Visual Checks

Before you use your electric winch, always start with a careful visual check. This step helps you spot problems early and keeps you safe. Put on gloves and safety glasses before you begin. Look at every part of your winch. Check for signs of wear, rust, or missing pieces. Pay close attention to the electrical wiring. Make sure there are no loose connections, damaged insulation, or signs of corrosion. Inspect the control panel. Test switches, emergency stop buttons, and safety interlocks to see if they work.

Tip: Never skip this step. A quick look can prevent big problems later.

Here is a simple checklist to follow:

Look for loose bolts, nuts, screws, or pins.

Check for cracks or corrosion on the winch body.

Make sure the winch sits securely on a stable surface.

Remove any foreign objects near the winch.

Test the winch with no load to see if it runs smoothly.

Listen for strange noises during operation.

A regular inspection helps you catch issues before they become dangerous.

Cable and Hook Condition

The cable and hook are critical parts of your electric winch. Damaged cables or hooks can fail and cause accidents. Always inspect your winch cable for kinks, fraying, or broken wires. Look for bulges, flat spots, or areas that look glossy. These signs may mean heat or internal damage. Run a cloth along the cable to feel for broken wires. Check for rust or chemical stains. If you find any of these problems, replace the cable right away.

For the hook, check for cracks, nicks, or deformation. Make sure the hook latch works and moves freely. Measure the hook opening with a gauge if you have one. The hook should not be bent or stretched. Industry standards like OSHA 1926.251 and ASME B30.9 give clear rules for checking cables and hooks. Always follow the manual for your marine electric winch to meet these standards.

Note: Never use a winch with a damaged cable or hook. Using the right winch for the job and keeping it in good shape protects you and your equipment.

Component Wear

Every part of your electric winch can wear out over time. Dirt, moisture, and heavy use speed up this process. Check the motor for signs of wear, like strange noises or heat. Look at the gears and bearings for vibration or oil leaks. Inspect the brake for signs of oil, worn bands, or weak springs. Make sure the controller and switches work without sticking or burning smells.

Common causes of wear include:

Lack of cleaning and lubrication

Overloading the winch

Bad installation or misalignment

Old age and frequent use

Harsh weather or salty air, especially for a marine electric winch

If you find any worn or damaged parts, replace them right away. Do not wait for a breakdown. Keeping a record of each inspection helps you track wear and plan maintenance.

Safety Reminder: Always use trained personnel for detailed checks and repairs. Follow the manual for your winch and keep inspection records up to date.

Lubrication and Cleaning

Lubricate Moving Parts

You must keep your electric winch working well. Lubrication is a big part of daily care. Always use marine-grade lubricants on gears, bearings, shafts, and the drum. These lubricants help stop rust and lower friction. Clean the moving parts before you add any lubricant. This removes dirt and old grease. Cleaning first helps stop contamination.

Here are some steps to follow:

Find all important spots, like gears, bearings, and shafts.

Use the right amount of lubricant the manufacturer suggests.

Keep a regular schedule based on how much you use the winch and where you use it.

Do not use too much grease. Too much can bring in dirt and cause harm.

Tip: Lubricate your winch often as part of daily care. This helps your winch work its best and last longer.

Clean After Use

Cleaning your winch after each use is very important. Brush off loose dirt and use compressed air for tight spots. Pick cleaning products that are safe for your winch. Mild soap and water work for most parts. Focus on drums, gears, and bearings. These places get the most dirt.

After cleaning, dry every part to stop rust. Clean parts make it easier to find problems next time you check. Good cleaning habits help your winch work better and make maintenance easier.

Keeping your winch clean and well-lubricated keeps it safe and protects your investment.

Electrical Checks

Power and Wiring

Check the power supply and wiring before using your electric winch. Bad wiring or weak batteries can make the winch stop or move slowly. Use a multimeter to test the battery voltage. If the battery loses power fast or the winch is slow, the battery may be weak or there could be a power problem. Always look at the wiring for damage, loose parts, or rust. Change any broken wires right away.

Here is a table of common electrical faults and how you can find them:

Electrical Fault / Symptom |

Possible Cause |

Detection / Troubleshooting Method |

|---|---|---|

Battery draining quickly |

Weak or faulty battery |

Use multimeter to check voltage; recharge or replace battery |

Winch operating slowly |

Battery issues or power draw |

Inspect battery condition; check for obstructions; lubricate drum |

Motor unresponsive |

Electrical connection problems |

Check and tighten connections; replace blown fuses |

Circuit breaker blows immediately |

Blown rectifier bridge |

Replace rectifier bridge; check wiring per diagram |

Damaged wiring |

Causes circuit breakers to blow |

Inspect wiring for damage; look for blown breakers |

Tip: Unplug the remote when you finish using the winch. This step helps stop the winch from turning on by accident.

Motor and Controls

Check the motor and controls every time you use your winch. Watch the motor to see if it gets too hot. If the motor runs for more than 45 seconds or stops, let it cool for 10 minutes. This keeps the motor from getting too hot or breaking. Test the remote to see if it works well. Make sure all switches work as they should.

Follow these steps for a safe check:

Listen for odd sounds or feel if the motor is hot.

Test the remote and switches to see if they work.

Make sure the emergency stop works before you start.

Keep your hands, clothes, and jewelry away from moving parts.

Never touch the cable when it is moving or pulling.

Be ready for emergencies. Know where the emergency stop is and how to use it. This can help you stop the winch fast if something goes wrong.

Winch Safety Measures

Load Limits

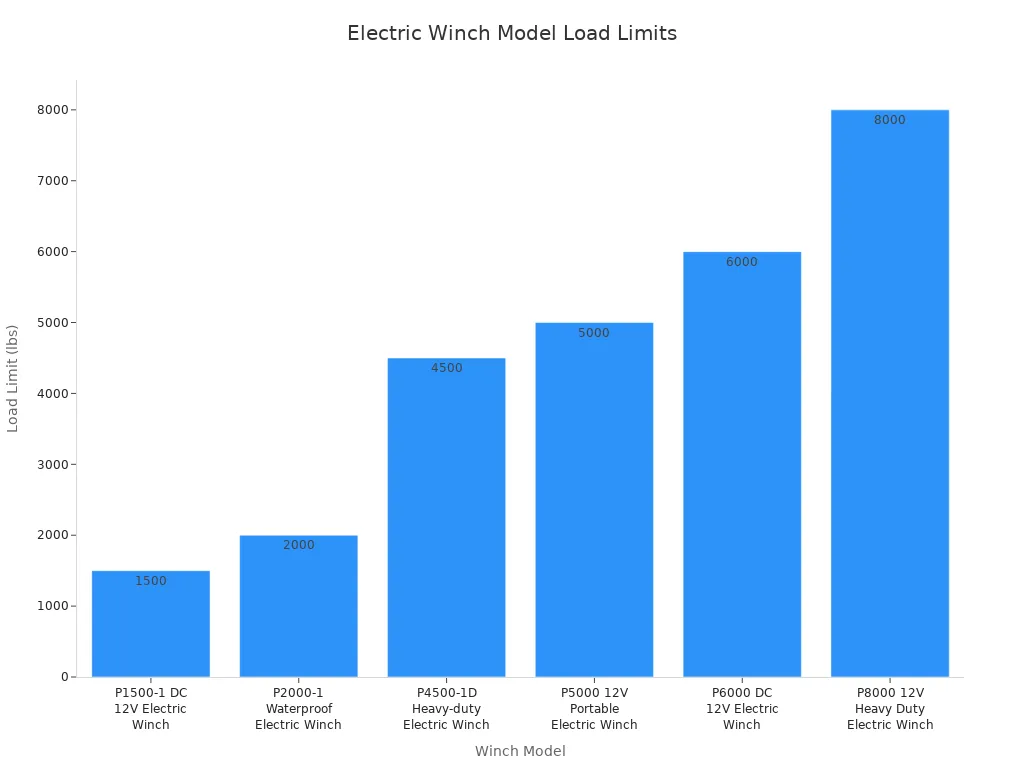

You must always follow the rated load limits for your electric winch. Each model can only pull a certain amount of weight. If you try to pull more, it can break and cause accidents. The table below shows how much weight each popular electric winch model can handle:

Model Name |

Rated Load Limit (lbs) |

|---|---|

P1500-1 DC 12V Electric Winch |

1500 |

P2000-1 Waterproof Electric Winch |

2000 |

P4500-1D Heavy-duty Electric Winch |

4500 |

P5000 12V Portable Electric Winch |

5000 |

P6000 DC 12V Electric Winch |

6000 |

P8000 12V Heavy Duty Electric Winch |

8000 |

Manufacturers say you should pick a winch that can pull about 1.5 times your vehicle’s weight. This keeps you safe when you need to pull or rescue something. Never pull more than the Safe Working Load (SWL) or line pull limit. Pulling winches are not as strong as lifting hoists, so overloading is risky.

Tip: Always read the label on your winch before you use it. If you need to test the load, follow the manual and never go over the limit.

If you ignore load limits, these things can happen:

The device can break badly

The cable or rope might snap

Gears can get ruined

You can lose control of the load

People or things can get hurt

Following the right load limits is very important for winch safety. It keeps you and your gear safe.

Proper Setup

A safe setup is the first step for safe use. Before you start, look at your area and check the weight. Make sure it does not go over the winch limit. Use these steps for a good setup:

Mount the winch to a strong anchor that can hold the weight.

Attach the cable or rope tightly and spool it right.

Connect the winch to the right power and check all wires.

Test the controls to make sure everything works.

Use the winch the way the manual says.

Stand away from the cable and wear gloves.

Stop right away if you see any problems.

Keep the area around the winch clean and clear. Use good anchors, like tree protectors, if you use trees. Always pay attention and talk to others while using the winch. Never leave the winch running without someone watching.

Note: Doing regular checks, cleaning, and looking at the cable helps keep things safe and stops accidents.

Safety Gear

Personal Protective Equipment

You need the right gear to stay safe with an electric winch. Personal protective equipment keeps you from getting hurt and helps you feel sure of yourself. Always put on gloves to keep your hands safe from sharp cables or quick moves. Wear safety glasses or goggles to protect your eyes from flying pieces or broken wires. Wear clothes that fit close to your body so nothing gets caught in moving parts. If it is loud, use earplugs to protect your ears. You should also cover the cable with a heavy blanket or a winch damper when it is tight. This cover soaks up energy if the cable snaps and gives you more safety.

Gloves keep your hands safe

Safety glasses or goggles protect your eyes

Fitted clothes stop things from getting caught

Earplugs help with loud sounds

Heavy blanket or winch damper keeps the cable safer

Always look at your gear before you start. Good gear and training help you follow safety rules every time you use your winch.

Safe Distances

You must stand far enough away when using an electric winch. People should stay at least one and a half to two times the cable’s length away. For example, if the cable is 20 feet, everyone should stand about 30 feet away. This space keeps people safe if the cable breaks or the winch stops working. Always remind others about these rules before you start using the winch. Keeping the area clear is one of the best ways to keep everyone safe.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.